Related Resources: calculators

C-Section No. 2 of 1b Loading Concentrated Intermediate Torque applied Deflection and Stress Equatio

C-Section with Concentrated Intermediate Torque applied Deflection and Stress Equations and Calculator #2 of 1b Loading .

Loading configuration left end free to twist and warp right end fixed (no twist or warp).

Formulas for the elastic deformations of uniform thin-walled open members under torsional loading.

Per. Roarks Formulas for Stress and Strain - Formulas for torsional properties and stresses in thin-walled open cross sections, Table 10.2.

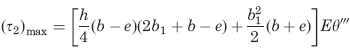

Section Dimensional Definitions

Figure 1

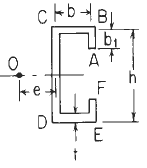

Loading Configuration (Section Shown May not Match Section given in Figure 1)

Loading configuration left end free to twist and warp right end fixed (notwist or warp)

Figure 2

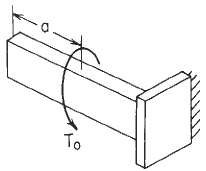

Loading Declarations Image (Section Shown May not Match Section given in Figure 1)

Concentrated intermediate torque of C-Section Beam Orientation Declarations Image

Figure 3

Preview: C-Section thin wall stress and torsional properties #2b calculator

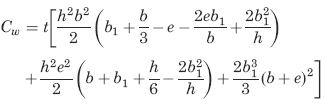

C-Section Properties Constants Formulas See: Figure 1

![]()

![]()

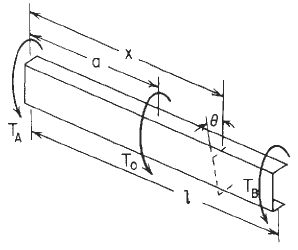

Selected maximum values of stress and torsion

![]()

Stress throughout the thickness at corners A and D

|

Shear stress due to warping rigidity Throughout the thickness on the top and bottom flanges at |

|

Shear stress due to torsional rigidity

![]()

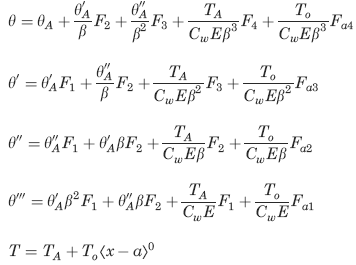

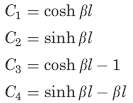

Left end free to twist and warp right end fixed (no twist or warp)

Boundary values for Loading condition See Figure 2

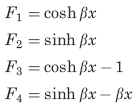

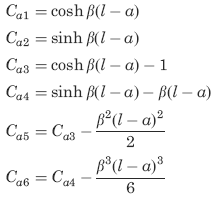

The following constants and functions are hereby defined in order to permit condensing the tabulated formulas which follow.

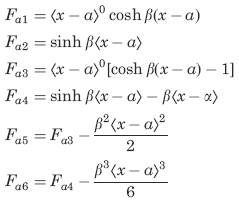

Concentrated intermediate torque See Figure 3

![]()

Where (when used in equations and this calculator):

Point 0 indicates the shear center se "Concentrated intermediate torque of Channel Beam Orientation Declarations image ";

e = distance from a reference to the shear center (in, m);

K = torsional stiffness constant (in4, m4);

C =warping constant (in6, m6);

τ1 = shear stress due to torsional rigidity of the cross section (lbsf/in2, m2);

τ2 = shear stress due to warping rigidity of the cross section (lbsf/in2, m2);

σx = bending stress due to warping rigidity of the cross section (lbsf/in2, m2);

E = modulus of elasticity (lbs/in2, m2);

G = modulus of rigidity (shear modulus) of the material (lbs/in2, m2);

To = applied torsional load (in-lbs, N-m);

to = applied distributed torsional load (lbsf/in, N/m);

TA and TB are the reaction end torques at the left and right ends, respectively (in-lbs, N-m);

θ = angle of rotation at a distance x from the left end (radians).

θ', θ'', θ''', = are the successive derivatives of y with respect to the distance x;

Cw = the warping constant for the cross section;

A, B, C, D, E, F, e, h, b1= Dimensional data Figure 1 (in, m).

All rotations, applied torsional loads, and reaction end torques are positive as shown (CCW when viewed from the right end of the member)

Unit step function defined by use of ⟨ ⟩

⟨ x - θ ⟩0

if x < a, ⟨ x - a ⟩n =0;

if x > a, ( x - a) n ;

The function sinh β

β = ( KG/CwE)1/2

Supplemental selected special cases and maximum values (not included in calculator), See Figure 2.

Reference:

Roarks Formulas for Stress and Strain, 7th Edition, Table 10.2 and 10.3 Formulas for torsional properties and stresses in thin-walled open cross sections.