Related Resources: calculators

Poppet Seal Gasket O-ring Operating Life and Reliability Equations and Calculator

Application and Design Engineering

General Engineering and Design

Poppet Seal Gasket Oring Operating Life and Reliability Equations and Calculator

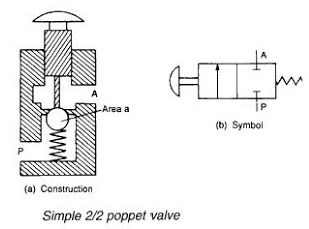

The primary failure mode of a seal is leakage, and the following equation is a approach developed for evaluating a poppet valve design.

Preview: Compression Spring Assembly Operating Life and Reliability Calculator

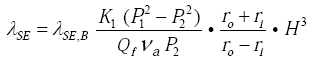

Poppet valve seal reliability equation:

Where:

λSE = Failure rate of seal, failures/million cycles

λSP,B = Base failure rate of seal, failures/million cycles

K1 = Constant = 3.27 x 10-4

P1 = System pressure, lb/in2

P2 = Standard atmospheric pressure or downstream pressure, lb/in2

Qf = Allowable leakage rate under conditions of usage, in3/min

?a = Absolute fluid viscosity, lb-min/in2

ri = Inside radius of circular interface, in

ro= Outside radius of circular interface, in

H = Conductance parameter (Meyer hardness M; contact pressure C; surface finish ƒ), in

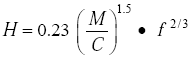

The conductance parameter is a combination of Meyer hardness, contact pressure and surface finish per the following equation:

Where:

M = Meyer hardness (or Young's modulus) for rubber and resilient materials, lbs/in2

C = Contact stress, lbs/in2

ƒ = Surface finish, in

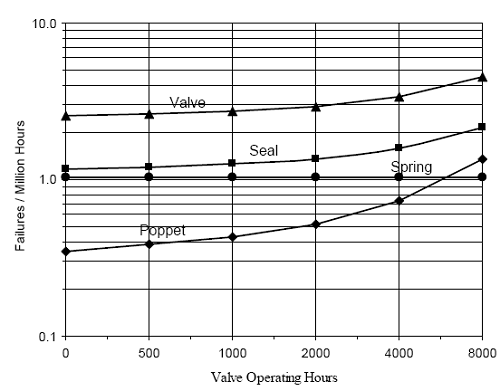

In the case of an O-ring seal, the failure rate will increase as a function of time because of gradual hardening of the rubber material. A typical failure rate curve for an O-ring is shown below:

References:

Handbook of Reliability Prediction Procedures for Machine Equipment

Related:

- Reliability Handbook

- Concurrent Engineering Electronic Circuit Design

- ORing Installation Design and Specification Static Cylindrical Installations

- O-Ring Installation Design and Specification Static Flange Application

- O-Ring Installation Design and Specification For Dynamic Applications

- O-Rings Design Guidelines, Specifications, Materials

- O-Ring Installation Compressive Load vs Hardness Chart .210 Diameter O-Ring