Related Resources: calculators

Shaft Keyway Shear and Yield Strength Formulae and Calculator

Strength and Mechanics of Materials

Gear Design and Engineering Data

Machine Design Applications

Shaft Keyway Shear and Yield Strength Requirements Formula and Calculator

Design tip for shaft and keyways: In general, shafting up to 3 inches in diameter is almost always made from cold-rolled steel. This shafting is true and straight and needs no turning, but if keyways are cut in the shaft, it must usually be straightened afterwards, as the cutting of the keyways relieves the tension on the surface of the shaft produced by the cold-rolling process. Sizes of shafting from 3 to 5 inches in diameter may be either cold-rolled or turned, more frequently the latter, and all larger sizes of shafting must be turned because cold-rolled shafting is not available in diameters larger than 5 inches.

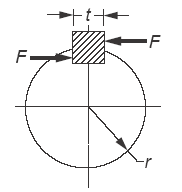

Figure 1 Shaft Keyway Dimensional

Preview Premium Access Only Shaft Keyway Shear and Yield Strength Required Calculator

Eq. 1

Keyways in Shaft or Hub

Ssy / n = F / t · l

Rearrange for shear strength

Eq. 2

Shaft or axle diameter required

Ssy = n · F / ( t · l )

Eq. 3

Keyways in Shaft or Hub

Sy / n = F / [ ( t · l ) / 2 ]

Rearrange for yield strength

Eq. 4

Keyways in Shaft or Hub

Sy = n · F / [ ( t · l ) / 2 ]

where

n = safety factor, %;

F = force applied, lb

Ssy = shear strength, lbs/in2 (psi);

Sy = yield strength, lbs/in2 (psi);

t = key / keyway width, in;

l = length of keyway, in ;

Effect of Keyways on Shaft Strength. Keyways cut into a shaft reduce its load carrying ability, particularly when impact loads or stress reversals are involved. To ensure an adequate factor of safety in the design of a shaft with standard keyway (width, one-quarter, and depth, one-eighth of shaft diameter), the former Code for Transmission Shafting tentatively recommended that shafts with keyways be designed on the basis of a solid circular shaft using not more than 75 percent of the working stress recommended for the solid shaft.

Source:

- Budynas, Richard G., and J. Keith Nisbett, Shigley's Mechanical Engineering Design, 8th ed., New York: McGraw-Hill, 2008.

- Marks Standard Handbook for Mechanical Engineers

- Machinerys Handbook, 30th Edition

Related:

- Standard Metric Keys Keyways for Metric Bores with One Key

- Keyway Cutter Hole Keyway Dimensional Data for MIlling Centers and Arbors - ANSI/ASME B94.19-1997

- Keyway Stresses for Non-metallic Gears and Shafts Formulas and Calculator

- Shaft (Arbor) Keyway Dimensional Data - ANSI/ASME B94.19-1997

- Design of Square Key and Keyway (Wood Ruff) Stress, Shear and Torque

- Metric Key Keyway Dimensions

- Parallel Key and Taper Keys Dimensions

- Shaft with Keyway Torque Applied Deformation and Stress Equations and Calculator

- Shaft with Two Keyways Torque Applied Deformation and Stress Equations and Calculator