Related Resources: calculators

Split Ring Planetary Gearbox Python Script Application

Split Ring Planetary Gearbox Python Script Application and Calculator

This is a collection of Python scripts for designing a Split Ring Planetary Gearbox.

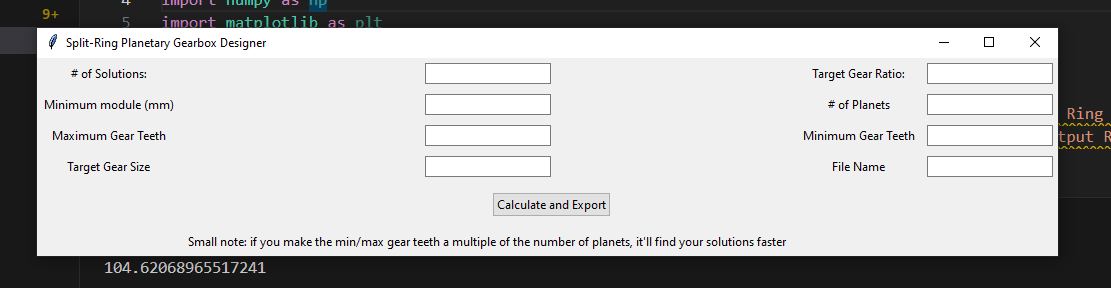

This is a really simply python script that helps design split-ring planetary compound gearboxes. The _gui.py script runs a Tkinter gui that allows for easy use and exports your desired number of solutions to a .csv file

Python code - This application requires knowledge of Python installation and code execution.

NOTE:

Refunds are not awarded after Python files have been downloaded - review your membership agreement for details.

Units (if utilized) utilized within calculators are either SI or Imperial (some enable both SI and Imperial) and member (you) are responsible for conversions. Ensure that you verify units utilized in excel application meet your requirements before downloading.

Premium Membership Required for download

Download: Split Ring Planetary Gearbox Python Calculators

Helps generate planetary gear combinations:

- number of teeth for sun, planets, outer ring

- output gear ratio

- module/sizes

Only works with split-ring compound planetary gears that are driven via first stage sun gear and output through second/last stage's outer ring, AKA split-ring

Example output excel data file - Split Ring Planetary Gearbox

Figure 1 Gear Input data GUI

Source

Python code - This application requires knowledge of Python installation and code execution.

Support:

- Engineers Edge has tested the basic functions and operation of this application using Python 3.11.9 and supporting modules.

- THE SOFTWARE IS PROVIDED "AS IS", WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT. IN NO EVENT SHALL THE AUTHORS OR COPYRIGHT HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM, OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN THE SOFTWARE.

Related

- Classification and Accuracy Tolerances for Coarse-Pitch Spur and Helical Master Gears An inspection master gear is used with selected fixtures to measure the variations in a manufactured gear.

- Spur Gear Generator with Download Spur Gear Generator is unitless: you may choose inches, cm or millimeters when importing your DXF file as you will have the same value for D/P as it is set above or as imported (SI or imperial units).

- Spur Gear and Assembly Builder Spur Gear and Assembly Builder calculates and models individual Spur Gears and Gear assembly. File down loads available with Premium Account.

- AGMA Allowable Contact Stress, s ac , for Steel Gears Table The allowable stress numbers for gear materials vary with items such as material composition, cleanliness, residual stress, microstructure, quality, heat treatment, and processing practices. For materials other than steel, a range is shown, and the lower values should be used for general design purposes.

- AGMA Contact Stress Number Formula for Gear Tooth Equation and Calculator Per standard ANSI/AGMA D04 Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth:

- AGMA Gear Tooth Bending Stress Formula and Calculator Per standard ANSI/AGMA D04 Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth:

- AGMA Major metallurgical factors affecting the allowable contact stress number , s ac , and allowable bending stress number

- Gear Design Handbook Premium Membership Required

- AGMA Spur Gear Profile Calculator Spread Sheet - Three excel calculation sheets that include the following input data/variables, calculated data and chart graphics.

- AGMA Worm and Spur Gear Design Equations and Calculators Worm gear sets are generally rated by their capacity to handle a particular level of input power, output power, or allowable torque at a particular speed for the input or output shaft.

- AGMA Worm gear Equations For Rating Factors Values for the ratio correction factor, the velocity factor, and materials factors can be found from tables provided in the ANSI/AGMA 6034-B92 standard.

- Practical Gear Design and Manufacture Handbook 872 pages, Premium account required, Gears are produced in enormous amounts - billions of gears are produced by industries every year. While the automotive industry ranks as the primary consumer of gears, numerous other industries also require huge amounts of gears: aerospace (helicopter transmission, etc. ), construction machinery, and agricultural machinery, to name a few.

- Sprocket Pitch Diameter Formulas and Calculator The sprocket pitch diameter is an imaginary circle through which the chain pin centers move around the sprocket.

- Torque in Gear Drives Formulas The lever arm of a gear is half of its reference diameter d.

- Chain Length For Two Sprockets Formulas and Calculator It is sometimes necessary to fix the center-to-center distance of the sprockets to accommodate existing constraints or mechanical design considerations.

- Shaft Keyway Shear and Yield Strength Requirements Formula and Calculator

- Spur and Helical Gear Mechanical Drawing Specifications Requirements Defining a gear for manufacturing, or procurement requires engineering and manufacturing information.

- Spur Gear Train Backlash Review Spur gear backlash is the amount of tooth space between mating gears at the pitch circle diameter.