Related Resources: calculators

Stress at Threaded Tube Connection Design Calculator

Threaded Connections Design and Calculations

Strength of Materials

Stress at Threaded Connections Between Two Tubes Design and Calculator

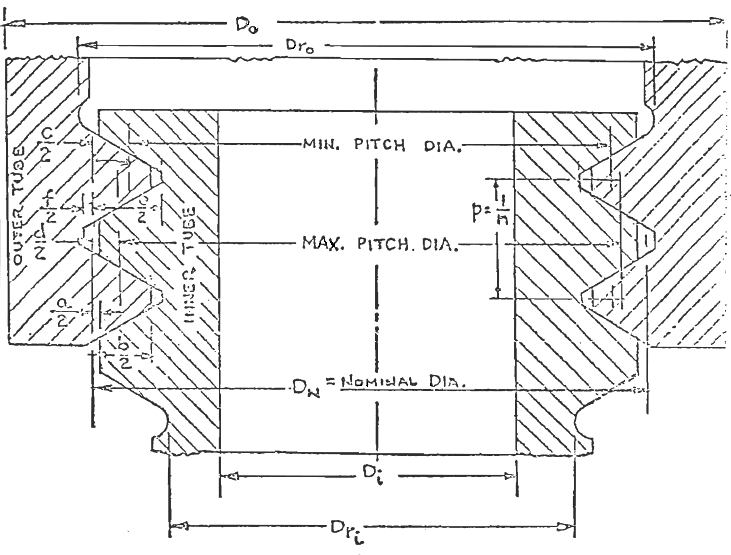

The following rules are stated for the case of threaded connections between two tube subjected to axial force, P. For the bolt-and-nut assembly, the same rules apply, by substituting Di = O.

Preview calculator: Design Stress at Threaded Connections Between Two Tubes Calculator

Eq. 1 Tensile stress in outer tube at root section of thread

Eq. 2 Tensile stress in outer tube at relief groove

Eq. 3 Tensile stress in inner tube at root section of thread

Eq. 4 Tensile stress in inner tube at relief groove

Eq. 5 Shear stress across threads, along a cylindrical surface having a diameter equal to the minimum pitch diameter.

Eq. 5a

Eq. 5b

Eq. 5c Unloaded tooth

Utooth = Δo - ΔI

Figure 1 - Tube to Tube threaded Connection

Eq. 6 Bearing stress on the surface of contact between inner and outer threads.

Eq. 7 Hoop compression stress in inner tube

Eq. 7a The corresponding elastic decrease in diameter of the inner tube is

Eq. 8 Hoop tension stress in outer tube

Eq. 8a

Where

P =axial tensile force

DN = Nominal diameter

Do = Outer tube thread root diameter

Dro = Outer tube major diameter

Di = Inside tube inside diameter

Dri = Inside tube root diameter

L = Length of engagement

ΔI = elastic decrease in diameter of inner tube

ΔO = elastic increase in diameter of outer tube

a = Truncation of external thread root

b =

Total single thread contact width

p = pitch

c = Difference between maximum major and pitch diameter of internal thread

d = Height if internal thread and depth of thread engagement

e = Double height of external thread

f = Addendum of external thread

ft = Tensile stress

Utooth = Unloaded tooth height

Ltooth = Loaded tooth height

L = Length of engaged thread

Reference:

- Bell Helicopter Structural Design Manual, 1977

Unloaded Tooth Height

Related

- Screw Thread Size Chart

- Length of Screw Thread Engagement per. ISO 965-1 Calculator , Formula and Table Length of engagement of mating threads is selected to utilize full tensile strength of a bolt prior to shearing and nut threads.

- Bolt Fastener Tightening Methods Review

- Bolt Head or Nut Friction Torque Formula and Calculator per. MIL-HDBH-60

- Bolt Elongation Stress Formulas and Calculator per. MIL-HDBH-60 Micrometer Bolt Elongation Method: Below the proportional limit. bolt elongation is directly proportional to axial stress, i.e., elongation increases in the same proportion as stress increases.

- Bolt Fastener Preload Torsion Load Stress Formulas and Calculator per. MIL-HDBH-60

- Bolt Elongation by Turn Formulas and Calculator per. MIL-HDBH-60

- Bolt Torque on Assembly for Gasket Contact Stress per. ASME PCC-1 Equations and Calculator

- Torque Clamp Force Calculator

- Stud Preload Calculator

- Bolt Preload Tension Equation and Calculator

- Bolt Preload Tension Force Calculator

- Torque vs Tension Bolts Table Chart SAE J429 Bolts

- Bolt Multiple Diameters Change of Length Under Axial Force Formula and Calculator