Related Resources: calculators

Theoretical Minimum Assembly Part Efficiency Calculator

Design for Manufacturing and Assembly

Theoretical Minimum Assembly Part Efficiency Calculator

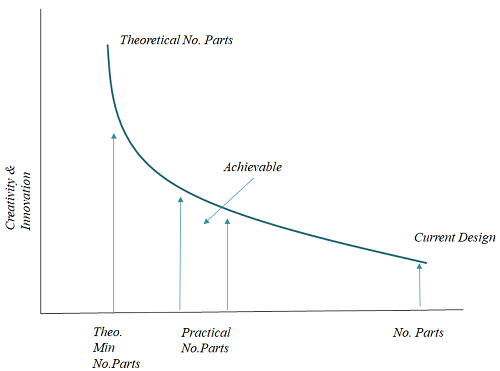

This calculator is used to determine if the optimal number of parts are being used in an assembly. 100% = perfect though eliminating the sub-assembly in the target end item assembly is desirable.

General Rule of Thumb Part Efficiency Goal > 50% or 1 to zero parts.. The minimum theoretical part count can be most always assumed to be equal to the number of required moving parts for functions.

Eq. 1

Te = Tmin / Tp * 100

Declarations

Te = Theoretical Part Count Efficiency, %

Tmin = theoretical number of parts (moving =2, static assembly =1)

Tp = Actual number of parts

Related:

- Design for Producibility

- Design For Manufacturing Considerations DFM&DFMA and Training

- Six Sigma for Electronics Design and Manufacturing

- Design for Manufacturability and Concurrent Engineering

Credits:

Kelly L. Bramble, ASEM S-GDTP. FAA A&P,

Engineers Edge, LLC