Related Resources: calculators

Two Gears Sprocket Speed and Gear Ratio Equation and Calculator

Gears Engineering Design

Machine Design and Engineering

Two Gear or Sprocket Speed and Gear Ratio Equation and Calculator

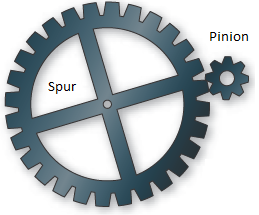

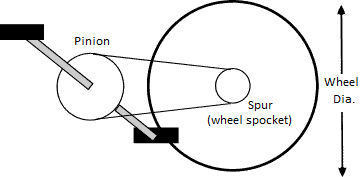

Typical Pinion and Spur Gear Arrangement

Bicycle Gear - Chain Ratio and Speed Ratio

Pinion Gear definition: A pinion is a round gear - usually the smaller of two meshed or chained together gears used in many applications and is the gear that drives or provides power to the gear train system.

Preview: Two Gear or Sprocket Speed and Gear Ratio Calculator

Gear Ratio is the number of teeth each gear represents when two gears are used in a mechanical component.

(Number of Teeth in Pinion Gear) / (Number of Teeth in Spur Gear) = Gear Ratio

Example: Pinion gear teeth = 8 and Spur gear teeth = 28,

Gear ratio = 8:28 or using 7 as the least common denominator (LCD) 2:7

Speed Ratio is when two gears are used in a component; the rotational speed of each gear is represented as a speed ratio. As the number of teeth in a gear decreases, the rotational speed of that gear increases, and vice-versa. Therefore, the speed ratio of two gears is the inverse (or opposite) of the gear ratio. Therefore, the speed ratio of two gears is the inverse (or opposite) of the gear ratio. If two gears have a gear ratio of 2:9, then their speed ratio is 9:2.

Gear Ratio to Speed Ratio Equivalency Equation:

(Number of Teeth in Pinion Gear) / (Number of Teeth in Spur Gear) = (Speed of Spur Gear) / (Speed of Pinion Gear)

Vehicle Velocity (mph) = Spur gear RPM * Wheel diameter (inches) * π * 60 (minutes/hr) / 63360 (in/hr)

or

Vehicle Velocity (km/h) = Spur gear RPM * Wheel diameter (mm) * π * 60 (minutes/hr) / 1x106 mm/hr

Wheel rpm = Speed of Pinion Gear

Related:

- Roller Chain Dimensions Table per. ASME/ANSI B29.1M

- Single Strand Roller Chain Number 35 Size Table

- Single Strand Roller Chain Number 40 Horsepower Ratings Table

- Flywheel and Shaft Torque Analysis

- Gear Terminology and Definitions

- Gear and Power Transmission Tables

- Roller Chain Tensile Strength vs. Horse Power