Related Resources: Fluids Engineering

Gas Compressibility Factor Spreadsheet Calculator

NOTE:

- Refunds are not awarded after excel files have been downloaded - review your membership agreement for details.

- This excel spreadsheet may contain macros which will need to be enabled in your excel application, see web page: Enable macros in Downloaded excel files

- Units utilized within calculators are either SI or Imperial (some enable both SI and Imperial) and member (you) are responsible for conversions. Ensure that you verify units utilized in excel application meet your requirements before downloading.

Engineering Excel Spreadsheet Downloads

Fluid Flow Design and Engineering

Hydraulic and Pneumatic Design and Engineering

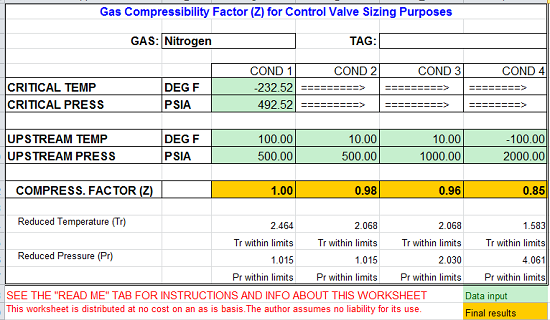

Gas Compressibility Factor Spreadsheet Calculator

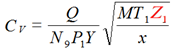

Equation 9 of the IEC and ISA control valve sizing equation standards, rearranged to solve for Cv, is:

were N9 is a constant that depends on the engineering units that will be used in the calculation.

This equation uses upstream pressure, upstream temperature, the molecular mass of the gas and the compressibility factor (Z) of the gas to include the upstream density of the gas in the Cv calculation. (I have highlighted "Z" in red, because that is the subject of this Excel worksheet.) The IEC/ISA standards include Z in their equation, but they do not make any suggestion as to how to determine its value. The compressibility factor is included to correct what would otherwise be the density based on the "Ideal gas equation" for the behavior of a real gas. The Ideal gas equation assumes that there is no interaction between gas molecules which in many cases there may be. It turns out that many of the gasses used in industrial processes, at the temperatures they are often used , have minimal interaction between molecules, so assuming that the Ideal gas equation is sufficient can be satisfactory for control valve sizing purposes. Entering a value of 1.0 for Z causes Equation 9 to use a density based on the Ideal gas equation. In cases where Z turns out to be significantly different than 1.0 the result can be mis-sizing of a control valve. For example, if the actual compressibility factor is 0.7, but a value of 1.0 is used in the calculation, the calculated Cv will be about 20% high.

Note: Accessing this resource requires an active Premium Membership with Engineers Edge

Download:

Gas Compressibility Factor Spreadsheet Calculator

Preview