Related Resources: HVAC Heating Ventilation Air Conditioning

Residential Duct Systems Design

NOTE:

- Refunds are not awarded after excel files have been downloaded - review your membership agreement for details.

- This excel spreadsheet may contain macros which will need to be enabled in your excel application, see web page: Enable macros in Downloaded excel files

- Units utilized within calculators are either SI or Imperial (some enable both SI and Imperial) and member (you) are responsible for conversions. Ensure that you verify units utilized in excel application meet your requirements before downloading.

Engineering Excel Spreadsheet Downloads

HVAC Design and Engineering

ACCA Manual D, 3rd Edition Residential Duct Systems Design Calculations Excel Spreadsheet

Description:

Use the printed D3 manual for guidance to enter information into the Effective Length, Friction Rate and Duct Sizing tabs.

Help Section

Refer to Manual D Residential Duct Systems, Third Edition Version 1.xx

Step 1:

- Go to the Effective Length Tab and enter up to 4 supply runs to determine the longest equivalent run in the system.

- Enter the linear feet of trunk and runout ducts in the length sections for the supply ducts.

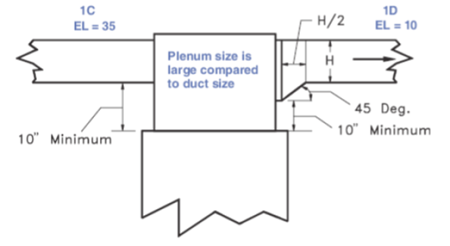

- Click on the Group Code and find the equivalent feet for all fittings used in the selected supply runs.

- The program will automatically select the "Total Equivalent Feet" to be used in the Friction Rate Tab.

- Repeat the steps above for the return ducts.

Step 2:

- Go to the Friction Rate Tab and enter the "External Static Pressure" and "CFM" for the selected equipment.

- Next enter "Component Pressure Losses" for all components and accessories external of the fan unit.

- The program will automatically calculate the "Design Friction Rate" value to be used for Duct Sizing.

Step 3:

- Go to the Duct Sizing 1 Tab and enter the heating and cooling BTUH for each supply run.

- There is a maximum of 14 supply runs per unit.

- For larger rooms divide the BTUH by the number of runs required for proper distribution of airflow.

- The program will automatically select the duct size for round metal ductwork.

- For rectangular metal ductwork enter the height and the program will automatically select the duct size.

- If Flex Duct is used refer to the Equivalent Flex column to select the correct duct size.

- Under the supply truck section, select the associated supply runs for this supply trunk section and the CFM will automatically calculate.

- The program will automatically select the duct size for round metal ductwork.

- For rectangular metal ductwork enter the height and the program will automatically select the duct size.

- If Flex Duct is used refer to the Equivalent Flex column to select the correct duct size.

- If more than four (4) supply trunk sections are required select the Duct Sizing 2 Tab .

- Repeat the steps above for the return ducts.

Preview: Residential Duct Systems Design Calculations Excel Spreadsheet

Note: Accessing this resource requires an active Premium Membership with Engineers Edge

Download: Residential Duct Systems Design Calculations Excel Spreadsheet