HEPA Filter Pressure Drop Considerations

By design, HEPA air filters will create resistance to flow, and a high differential pressure drop will exist across the filter. Most HEPA air filter manufacturers literature suggests replacement of HEPA air filters when the resistance due to dust loading has reached 2 in.wg.

The advantages of operating to high pressure drop must be weighed against initial costs (higher-static-pressure fans, larger motors, heavier ductwork), higher power costs, and less efficient fan operation. The installed fan and motor must have sufficient capacity to deliver the design airflow at the maximum differential pressure under which the system will operate, with the filters at maximum dirty-filter pressure drop prior to change. Therefore, consideration must not only be given to the increased installed capacity required to operate to the higher pressure drop, but also to the fact that the fan operates at a penalty much of the time to provide the required airflow over the wide span of pressure drop between installation and replacement of filters.

The cost of ductwork, on the other hand, may not be significantly affected by operation to a high pressure drop because there is a minimum sheet-metal thickness for effective welding, regardless of pressure. The cost of fans and motors is a function of the maximum total pressure that must be developed. Fan horsepower can be estimated from the following equations.

Motor horsepower can be estimated from the equation:

![]()

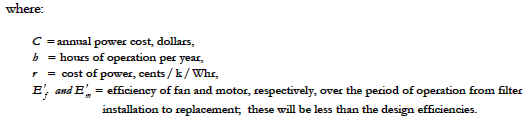

Annual power costs can be estimated from the following equation:

![]()

Although investment and power costs will be lower for systems operated to 2-in.wg pressure drop, the total annual cost of owning a system, including materials and labor costs for filter replacement, may be less for a system in which HEPA filters are replaced at pressure drops on the order of 4 in.wg. Total savings for the facility as a whole may be even greater when the reduced interruption of building or facility operations, such as clean rooms, due to the reduced frequency of filter change is taken into consideration.

Some pre-filters can be operated to higher pressure drops than recommended by their manufacturers (but such overuse must be supported by operating experience). This results in less frequent pre-filter changes than when pre-filters are changed at a pressure drop of only two or three times the clean-filter pressure drop, as recommended by most manufacturers. Care must be taken in selecting pre-filters. Because of the many types, efficiencies, configurations, and constructions available, the designer must specifically investigate the safe overpressure allowance for the particular model under consideration. Some benefit could also have been obtained by installing a screen or expanded metal grille on the downstream face of the pre-filters against which the filter cores could bear; in any event, screens or grilles would have prevented damage to the HEPA filters when pieces of pre-filter struck them.