Labyrinth Seal Review

Fluid Flow Table of Contents

Hydraulic and Pneumatic Knowledge

Labyrinth Seal Review

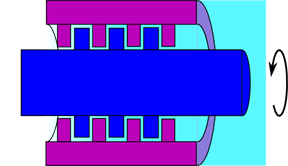

A labyrinth seal is a type of mechanical seal that provides a tortuous path to help prevent leakage. An example of such a seal is sometimes found within an axle's bearing to help prevent the leakage of the oil lubricating the bearing.

A labyrinth seal is composed of many straight grooves that press tightly inside another axle, or inside a hole, so that the fluid has to pass through a long and difficult path to escape. Sometimes screw threads exist on the outer and inner portion. These interlock, to produce the long characteristic path which slows leakage. For labyrinth seals on a rotating shaft, a very small clearance must exist between the tips of the labyrinth threads and the running surface.

|

|---|

Labyrinth seals on rotating shafts provide non-contact sealing action by controlling the passage of fluid through a variety of chambers by centrifugal motion, as well as by the formation of controlled fluid vortices. At higher speeds, centrifugal motion forces the liquid towards the outside and therefore away from any passages. Similarly, if the labyrinth chambers are correctly designed, any liquid that has escaped the main chamber, becomes entrapped in a labyrinth chamber, where it is forced into a vortex-like motion. This acts to prevent its escape, and also acts to repel any other fluid. Because these labyrinth seals are non-contact, they do not wear out.

Turbines use labyrinth seals due to the lack of friction, which is necessary for high rotational speeds.

Labyrinth seals are also found on pistons, which use them to store oil and seal against high pressure during compression and power strokes, as well as on other non-rotating shafts. In these applications, it is the long and difficult path and the formation of controlled fluid vortices plus some limited contact-sealing action that creates the seal.

Application include:

- Bearing seals

- Pump seals

- Lip seals

- Grease seals

- Piston seals