Related Resources: gears

Gear Design for Known Center Distance and Ratio

Gear Design for Known Center Distance and Ratio per. ANSI B6.7

Preview: Gear Design for Known Center Distance and Ratio

When it is necessary to use a pair of gears of given ratio at a specified center distance C1, it may be found that no gears of standard diametral pitch will satisfy the center distance requirement. Gears of standard diametral pitch P may need to be redesigned to operate at other than their standard pitch diameter D and standard pressure angle φ. The operating diametral pitch P1 at which these gears will operate is:

![]()

where:

Np = Number of teeth in pinion

NG = Number of teeth in gear

P1 = Operating diametral pitch (in, mm)

![]()

where:

φ1 = Operating pressure angle is

P = Diametral pitch as-built (in, mm)

P1 = Operating diametral pitch (in, mm)

Thus although the pair of gears are cut to a diametral pitch P and a pressure angle φ, they operate as standard gears of diametral pitch P1 and pressure angle φ1. The pitch P and pressure angle φ should be chosen so that φ1 lies between about 18 and 25 degrees.

The operating pitch diameters of the pinion Dp1 and of the gear DG1 are:

![]()

Base diameters of the pinion DPB1 and of the gear DGB1

![]()

![]()

Basic tooth thickness, t1, at the operating pitch diameter for both pinion and gear is:

![]()

Root diameters of the pinion DPR1 and gear DGR1

![]()

![]()

where:

![]()

![]()

bc is the hob or cutter addendum for the pinion and gear.

Tooth thicknesses of the pinion tP2 and the gear tG2 are

![]()

![]()

![]()

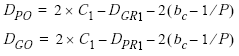

Outside diameter of the pinion DPO and the gear DGO :