Related Resources: hardware

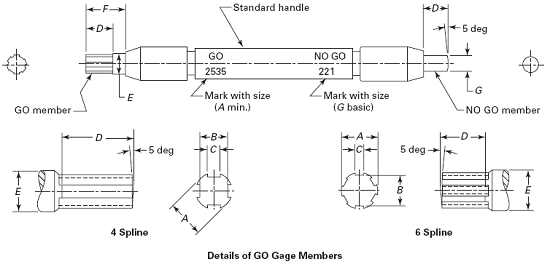

Spline Socket Go and No Go Gages

Dimensions of Go and No Go Gages for Spline Sockets per. ASME B18.3

Spline sockets in screws shall allow the GO member of the gage to enter freely to the minimum key engagement depths specified in the dimensional tables for the respective screw types.

For spline sockets that are not chamfered, the NO GO gage member shall not enter the socket.

For chamfered spline sockets, the NO GO gage member shall be permitted to enter only to a depth equivalent to 10% of the nominal socket size for nominal socket sizes up to and including 0.060 in., and to 7.5% of the nominal socket size for larger sockets.

Dimension units in inches.

Related:

Spline Socket Head Screws Size Table

|

Nom.

Socket Size |

Number

of Splines |

Go Gage

Major Dia. A |

Go Gage

Minor Dia. B |

Go Gage

Space Width C |

Min.

Gage Length D |

Shoulder |

Min.

Length F |

Basic

No Go Gage Dia. G Note 1 |

|||

|

Max.

|

Min.

|

Max.

|

Min.

|

Max.

|

Min.

|

||||||

|

0.033

|

4

|

0.0337

|

0.0335

|

0.0252

|

0.0250

|

0.0125

|

0.0123

|

0.0625

|

0.0350

|

0.093

|

0.0275

|

|

0.048

|

4

|

0.0487

|

0.0485

|

0.0372

|

0.0370

|

0.0175

|

0.0173

|

0.0625

|

0.0520

|

0.187

|

0.0395

|

|

0.048

|

6

|

0.0487

|

0.0485

|

0.0397

|

0.0395

|

0.0115

|

0.0113

|

0.0625

|

0.0520

|

0.187

|

0.0410

|

|

0.060

|

6

|

0.0607

|

0.0605

|

0.0497

|

0.0495

|

0.0145

|

0.0143

|

0.0625

|

0.0625

|

0.187

|

0.0510

|

|

0.069

|

4

|

0.0697

|

0.0695

|

0.0517

|

0.0515

|

0.0215

|

0.0213

|

0.0625

|

0.0700

|

0.187

|

0.0545

|

|

0.072

|

6

|

0.0727

|

0.0725

|

0.0627

|

0.0625

|

0.0165

|

0.0163

|

0.0625

|

0.0730

|

0.187

|

0.0640

|

|

0.076

|

4

|

0.0767

|

0.0765

|

0.0547

|

0.0545

|

0.0235

|

0.0233

|

0.0625

|

0.0770

|

0.187

|

0.0575

|

|

0.096

|

6

|

0.0967

|

0.0965

|

0.0797

|

0.0795

|

0.0225

|

0.0223

|

0.0938

|

0.0980

|

0.250

|

0.0820

|

|

0.111

|

6

|

0.1127

|

0.1125

|

0.0957

|

0.0955

|

0.0255

|

0.0253

|

0.0938

|

0.1130

|

0.250

|

0.0980

|

|

0.133

|

6

|

0.1347

|

0.1345

|

0.1157

|

0.1155

|

0.0305

|

0.0303

|

0.0938

|

0.1360

|

0.250

|

0.1180

|

|

0.145

|

6

|

0.1467

|

0.1465

|

0.1257

|

0.1255

|

0.0325

|

0.0323

|

0.1250

|

0.1470

|

0.250

|

0.1280

|

|

0.168

|

6

|

0.1707

|

0.1705

|

0.1467

|

0.1465

|

0.0365

|

0.0363

|

0.0938

|

0.1719

|

0.250

|

0.1500

|

|

0.183

|

6

|

0.1857

|

0.1855

|

0.1607

|

0.1605

|

0.0395

|

0.0393

|

0.1875

|

0.1875

|

0.375

|

0.1630

|

|

0.216

|

6

|

0.2187

|

0.2185

|

0.1877

|

0.1875

|

0.0505

|

0.0503

|

0.1875

|

0.2187

|

0.437

|

0.1900

|

|

0.251

|

6

|

0.2537

|

0.2535

|

0.2187

|

0.2185

|

0.0605

|

0.0603

|

0.2500

|

0.2570

|

0.500

|

0.2210

|

|

0.291

|

6

|

0.2957

|

0.2955

|

0.2517

|

0.2515

|

0.0685

|

0.0683

|

0.2500

|

0.2968

|

0.625

|

0.2540

|

|

0.372

|

6

|

0.3767

|

0.3765

|

0.3157

|

0.3155

|

0.0925

|

0.0923

|

0.3750

|

0.3770

|

0.750

|

0.3190

|

|

0.454

|

6

|

0.4597

|

0.4595

|

0.3827

|

0.3825

|

0.1125

|

0.1123

|

0.3750

|

0.4687

|

0.875

|

0.3860

|

|

0.595

|

6

|

0.6007

|

0.6005

|

0.5057

|

0.5055

|

0.1385

|

0.1383

|

0.5000

|

0.6094

|

1.000

|

0.5090

|

|

0.620

|

6

|

0.6267

|

0.6265

|

0.5307

|

0.5305

|

0.1495

|

0.1493

|

0.5000

|

0.6406

|

1.000

|

0.5350

|

|

0.698

|

6

|

0.7047

|

0.7045

|

0.5997

|

0.5995

|

0.1685

|

0.1683

|

0.5000

|

0.7187

|

1.125

|

0.6040

|

|

0.790

|

6

|

0.7967

|

0.7965

|

0.6807

|

0.6805

|

0.1895

|

0.1893

|

0.5625

|

0.7969

|

1.250

|

0.6850

|

Notes:

- Gages shall be made from any grade of steel, throughhardened and tempered to 60 HRC minimum.

- The form of hexagonal and spline gage members shall be within the tolerance zone specified. See ASME Y14.5M, Engineering Drawing and Related Documentation Practices, Dimensioning and Tolerancing.

- The surface roughness on hexagon and spline flats shall be 8 µin. (arithmetical average) maximum. See ASME B46.1, Surface Texture.

- The gage handles shall conform to ASME B47.1, Gage Blanks