Related Resources: hardware

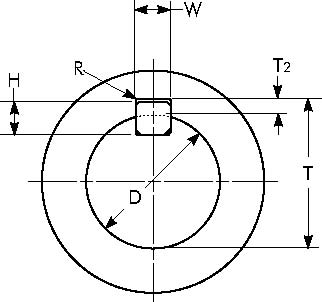

Standard Metric Keys Keyways for Metric Bores with One Key

Engineering Hardware Design Data

ISO Hardware Specifications Table

Standard Metric Keys & Keyways for Metric Bores with One Key

|

Metric Key & Keyway Dimensions Per ISO/R773 – P9 Width Tolerance H

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Shaft Diameter

|

Key Size

|

Keyway Width

|

Keyway Depth

|

Keyway Radius

|

||||||

|

"D"

|

Nominal

|

Hub "W"

|

Hub ""

|

"R"

|

||||||

|

Over

|

Thru

|

Width "W"

|

Height "H"

|

Nominal

|

Min

|

Max

|

Min

|

Max

|

Min

|

Max

|

|

6

|

8

|

2

|

2

|

2

|

-.031

|

-.006

|

1.0

|

1.1

|

0.08

|

0.16

|

|

8

|

10

|

3

|

3

|

3

|

-.031

|

-.006

|

1.4

|

1.5

|

0.08

|

0.16

|

|

10

|

12

|

4

|

4

|

4

|

-.042

|

-.012

|

1.8

|

1.9

|

0.08

|

0.16

|

|

12

|

17

|

5

|

5

|

5

|

-.042

|

-.012

|

2.3

|

2.4

|

0.16

|

0.25

|

|

17

|

22

|

6

|

6

|

6

|

-.042

|

-.012

|

2.8

|

2.9

|

0.16

|

0.25

|

|

22

|

30

|

8

|

7

|

8

|

-.051

|

-.015

|

3.3

|

3.5

|

0.16

|

0.25

|

|

30

|

38

|

10

|

8

|

10

|

-.051

|

-.015

|

3.3

|

3.5

|

0.25

|

0.40

|

|

38

|

44

|

12

|

8

|

12

|

-.061

|

-.018

|

3.3

|

3.5

|

0.25

|

0.40

|

|

44

|

50

|

14

|

9

|

14

|

-.061

|

-.018

|

3.8

|

4.0

|

0.25

|

0.40

|

|

50

|

58

|

16

|

10

|

16

|

-.061

|

-.018

|

4.3

|

4.5

|

0.25

|

0.40

|

|

58

|

65

|

18

|

11

|

18

|

-.061

|

-.018

|

4.4

|

4.6

|

0.25

|

0.40

|

|

65

|

75

|

20

|

12

|

20

|

-.074

|

-.022

|

4.9

|

5.1

|

0.40

|

0.60

|

|

75

|

85

|

22

|

14

|

22

|

-.074

|

-.022

|

5.4

|

5.6

|

0.40

|

0.60

|

|

85

|

95

|

25

|

14

|

25

|

-.074

|

-.022

|

5.4

|

5.6

|

0.40

|

0.60

|

|

95

|

110

|

28

|

16

|

28

|

-.074

|

-.022

|

6.4

|

6.6

|

0.40

|

0.60

|

|

110

|

130

|

32

|

18

|

32

|

-.088

|

-.026

|

7.4

|

7.6

|

0.40

|

0.60

|

|

130

|

150

|

36

|

20

|

36

|

-.088

|

-.026

|

8.4

|

8.7

|

0.70

|

1.00

|

|

150

|

170

|

40

|

22

|

40

|

-.088

|

-.026

|

9.4

|

9.7

|

0.70

|

1.00

|

|

170

|

200

|

45

|

25

|

45

|

-.088

|

-.026

|

10.4

|

10.7

|

0.70

|

1.00

|

|

200

|

230

|

50

|

28

|

50

|

-.088

|

-.026

|

11.4

|

11.7

|

0.70

|

1.00

|

|

230

|

260

|

56

|

32

|

56

|

-.106

|

-.032

|

12.4

|

12.7

|

1.20

|

1.60

|

|

260

|

290

|

63

|

32

|

63

|

-.106

|

-.032

|

12.4

|

12.7

|

1.20

|

1.60

|

|

290

|

330

|

70

|

36

|

70

|

-.106

|

-.032

|

14.4

|

14.7

|

1.20

|

1.60

|

|

330

|

380

|

80

|

40

|

80

|

-.106

|

-.032

|

15.4

|

15.7

|

2.00

|

2.50

|

|

380

|

440

|

90

|

45

|

90

|

-.124

|

-.037

|

17.4

|

17.7

|

2.00

|

2.50

|

|

440

|

500

|

100

|

50

|

100

|

-.124

|

-.037

|

19.5

|

19.8

|

2.00

|

2.50

|

| Metric Key & Keyway Dimensions Per ISO/R773 – D10 Width Tolerance | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Shaft Diameter

|

Key Size

|

Keyway Width

|

Keyway Depth

|

Keyway Radius

|

||||||

|

"D"

|

Nominal

|

Hub "W"

|

Hub "T"

|

"R"

|

||||||

|

Over

|

Thru

|

Width "W"

|

Height "H"

|

Nominal

|

Min

|

Max

|

Min

|

Max

|

Min

|

Max

|

|

6

|

8

|

2

|

2

|

2

|

+.020

|

+.060

|

1.0

|

1.1

|

0.08

|

0.16

|

|

8

|

10

|

3

|

3

|

3

|

+.020

|

+.060

|

1.4

|

1.5

|

0.08

|

0.16

|

|

10

|

12

|

4

|

4

|

4

|

+.030

|

+.078

|

1.8

|

1.9

|

0.08

|

0.16

|

|

12

|

17

|

5

|

5

|

5

|

+.030

|

+.078

|

2.3

|

2.4

|

0.16

|

0.25

|

|

17

|

22

|

6

|

6

|

6

|

+.030

|

+.078

|

2.8

|

2.9

|

0.16

|

0.25

|

|

22

|

30

|

8

|

7

|

8

|

+.040

|

+.098

|

3.3

|

3.5

|

0.16

|

0.25

|

|

30

|

38

|

10

|

8

|

10

|

+.040

|

+.098

|

3.3

|

3.5

|

0.25

|

0.40

|

|

38

|

44

|

12

|

8

|

12

|

+.050

|

+.120

|

3.3

|

3.5

|

0.25

|

0.40

|

|

44

|

50

|

14

|

9

|

14

|

+.050

|

+.120

|

3.8

|

4.0

|

0.25

|

0.40

|

|

50

|

58

|

16

|

10

|

16

|

+.050

|

+.120

|

4.3

|

4.5

|

0.25

|

0.40

|

|

58

|

65

|

18

|

11

|

18

|

+.050

|

+.120

|

4.4

|

4.6

|

0.25

|

0.40

|

|

65

|

75

|

20

|

12

|

20

|

+.065

|

+.149

|

4.9

|

5.1

|

0.40

|

0.60

|

|

75

|

85

|

22

|

14

|

22

|

+.065

|

+.149

|

5.4

|

5.6

|

0.40

|

0.60

|

|

85

|

95

|

25

|

14

|

25

|

+.065

|

+.149

|

5.4

|

5.6

|

0.40

|

0.60

|

|

95

|

110

|

28

|

16

|

28

|

+.065

|

+.149

|

6.4

|

6.6

|

0.40

|

0.60

|

|

110

|

130

|

32

|

18

|

32

|

+.080

|

+.180

|

7.4

|

7.6

|

0.40

|

0.60

|

|

130

|

150

|

36

|

20

|

36

|

+.080

|

+.180

|

8.4

|

8.7

|

0.70

|

1.00

|

|

150

|

170

|

40

|

22

|

40

|

+.080

|

+.180

|

9.4

|

9.7

|

0.70

|

1.00

|

|

170

|

200

|

45

|

25

|

45

|

+.080

|

+.180

|

10.4

|

10.7

|

0.70

|

1.00

|

|

200

|

230

|

50

|

28

|

50

|

+.080

|

+.180

|

11.4

|

11.7

|

0.70

|

1.00

|

|

230

|

260

|

56

|

32

|

56

|

+.100

|

+.220

|

12.4

|

12.7

|

1.20

|

1.60

|

|

260

|

290

|

63

|

32

|

63

|

+.100

|

+.220

|

12.4

|

12.7

|

1.20

|

1.60

|

|

290

|

330

|

70

|

36

|

70

|

+.100

|

+.220

|

14.4

|

14.7

|

1.20

|

1.60

|

|

330

|

380

|

80

|

40

|

80

|

+.100

|

+.220

|

15.4

|

15.7

|

2.00

|

2.50

|

|

380

|

440

|

90

|

45

|

90

|

+.120

|

+.260

|

17.4

|

17.7

|

2.00

|

2.50

|

|

440

|

500

|

100

|

50

|

100

|

+.120

|

+.260

|

19.5

|

19.8

|

2.00

|

2.50

|

Where:

T = D + T2

Related:

- Standard External Metric Thread and Fastener Sizes M 0.25 - M 1.4

- ANSI Woodruff Keys

- Shaft with Four Keyways Torque Applied Deformation and Stress Equations and Calculator

- Shaft with Keyway Torque Applied Deformation and Stress Equations and Calculator

- Metric Key Keyway Dimensions

- Parallel Key and Taper Keys Dimensions

- Shaft Keyway Shear and Yield Strength Formulae and Calculator

- Shaft (Arbor) Keyway Dimension Size Data - ANSI/ASME B94.19-1997

- Shaft Arbor and Keyseat Dimensional Data American National Standard Keys and Keyways

- Standard Metric Keys Keyways for Metric Bores with One Key

- Keyway Cutter Hole Keyway Dimensional Data for MIlling Centers and Arbors - ANSI/ASME B94.19-1997

- Keyway Stresses for Non-metallic Gears and Shafts Formulas and Calculator