Related Resources: hardware

Thrust Load Capacity Retaining Rings

ANSI Hardware Design Guide and Charts

Thrust Load Capacity of Retaining Rings

Thrust Load Capacity: The thrust load capacities shown in the table below include safety factors. Usually, a safety factor of 2 is used for groove thrust load calculations when the load is applied through a retained part and groove with both having sharp corners and where the minimum side clearance exists between the retained part and the shaft or bore.

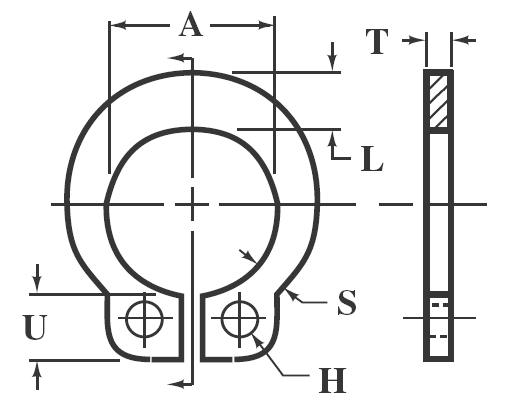

Dimensions of Inch Series Self-Locking External Retaining Rings

A safety factor of 3 is usual for calculations of thrust load capacity based on ring shear.

|

Shaft Diameter |

Ring |

Optical Groove |

1Static Thrust Load (lb) |

|||||

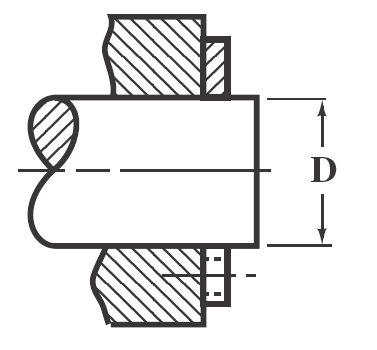

Min. D |

Max. D |

Free Dia. A |

Thickness T |

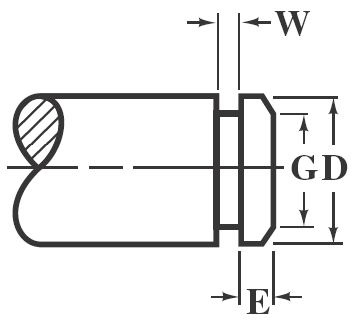

Diameter G |

Width W |

Margin E |

Ring |

Groove |

0.078 |

0.080 |

0.074 |

0.025 |

The use of grooves with these shaft sizes is not suggested. |

10 |

0 |

||

|

0.092 |

0.096 |

0.089 |

0.025 |

10 |

0 |

|||

|

0.123 |

0.127 |

0.120 |

0.025 |

20 |

0 |

|||

0.134 |

0.138 |

0.130 |

0.025 |

20 |

0 |

|||

0.154 |

0.158 |

0.150 |

0.025 |

22 |

0 |

|||

0.185 |

0.189 |

0.181 |

0.035 |

25 |

0 |

|||

0.248 |

0.252 |

0.238 |

0.035 |

0.240 |

0.041 |

0.030 |

35 |

90 |

0.310 |

0.316 |

0.298 |

0.042 |

0.303 |

0.048 |

0.030 |

50 |

110 |

0.373 |

0.379 |

0.354 |

0.042 |

0.361 |

0.048 |

0.030 |

55 |

185 |

|

0.434 |

0.440 |

0.412 |

0.050 |

0.419 |

0.056 |

0.030 |

60 |

280 |

|

0.497 |

0.503 |

0.470 |

0.050 |

0.478 |

0.056 |

0.040 |

65 |

390 |

0.622 |

0.628 |

0.593 |

0.062 |

0.599 |

0.069 |

0.045 |

85 |

570 |

0.745 |

0.755 |

0.706 |

0.062 |

0.718 |

0.069 |

0.050 |

90 |

845 |

1 Thrust Load Safety Factors: Ring, 1; groove, 2.

Source: Industrial Retaining Rings, 7100 Series. All dimensions are in inches. Depth of groove d = (D − G)/2. Standard material: carbon spring steel (SAE 1060-1090). Thickness indicated is for unplated rings; for plated, phosphate coated, and stainless steel rings, the maximum ring thickness may be exceeded by 0.002 inch.

Related: