Related Resources: heat transfer

Exergy Analysis of a Refrigeration Cycle Python Application Calculator

Exergy Analysis of a Refrigeration Cycle in TESPy Python Application and Calculator

Example for the exergy analysis in TESPy. Find more information about the exergy analysis feature in the respective online documentation.

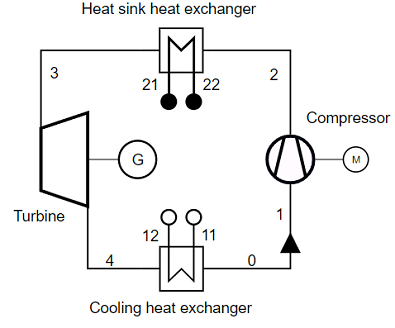

This is a Python script for calculations of a refrigeration cycle modelthat has the following topology:

Python code - This application requires knowledge of Python installation and code execution.

Premium Membership Required for download

Download: Heat Transfer Problems Solved Python Calculators

Find the model specifications and results in the refrigeration.py script and the corresponding pdf model report

Valdiation and Results of Exergy Analysis

The tables below show the results of the simulation as well as the validation results. The original data from the publication are provided in the .csv files component_validation.csv and connection_validation.csv .

Connection data

TESPy simulation

| 0 | 5.8 | 5.8 | 0.0 | 23.98 | 23.98 | 0.00 |

| 1 | 5.8 | 5.8 | 0.0 | 23.98 | 23.98 | 0.00 |

| 2 | 163.9 | 22.1 | 141.8 | 674.08 | 90.85 | 583.23 |

| 3 | 137.8 | 0.2 | 137.6 | 566.77 | 0.68 | 566.09 |

| 4 | 17.1 | 12.9 | 4.2 | 70.28 | 53.11 | 17.17 |

| 11 | 2.2 | 2.2 | 0.0 | 22.31 | 22.31 | 0.00 |

| 12 | 3.8 | 3.8 | 0.0 | 37.82 | 37.82 | 0.00 |

| 21 | 0.1 | -0.0 | 0.1 | 0.40 | -0.00 | 0.40 |

| 22 | 1.6 | 1.5 | 0.1 | 12.47 | 12.07 | 0.40 |

Absolute difference in the values Δ

| 1 | -0.085 | 0.0 | 0.00 | 0.0 | 0.0 | 0.0 |

| 2 | -0.085 | 0.2 | 0.00 | 0.1 | 0.0 | -0.0 |

| 3 | -0.085 | -0.0 | -0.00 | -0.7 | 0.0 | -0.0 |

| 4 | -0.085 | -0.4 | 0.00 | -0.5 | 0.0 | 0.0 |

| 11 | -0.023 | 0.0 | 0.00 | 0.1 | 0.0 | 0.0 |

| 12 | -0.023 | 0.0 | 0.00 | 0.1 | 0.0 | 0.0 |

| 21 | -0.106 | 0.0 | 0.00 | 0.0 | -0.0 | 0.0 |

| 22 | -0.106 | 0.0 | 0.00 | -0.0 | -0.0 | 0.0 |

Relative deviation in the values δ

| 1 | -2.024 | -0.0 | 0.0 | nan | 0.2 | nan |

| 2 | -2.024 | 0.1 | 0.0 | 0.0 | 0.5 | -0.1 |

| 3 | -2.024 | -0.0 | -0.0 | -1.0 | 10.7 | -0.0 |

| 4 | -2.024 | 0.7 | 0.0 | 2.2 | 1.4 | 0.1 |

| 11 | -0.229 | -0.0 | 0.0 | 0.6 | 0.2 | nan |

| 12 | -0.229 | -0.0 | 0.0 | 0.6 | 0.1 | nan |

| 21 | -1.328 | 0.0 | 0.0 | nan | -inf | 0.3 |

| 22 | -1.328 | 0.0 | 0.0 | -0.0 | -0.3 | 0.3 |

Deviation due to differences in fluid property data

Component data

TESPy simulation

| Cooling heat exchanger | 46.30 | 15.51 | 30.79 | 33.5 | 7.0 | 7.5 |

| Compressor | 815.29 | 674.08 | 141.21 | 82.7 | 32.1 | 34.3 |

| Heat sink heat exchanger | 107.31 | 12.07 | 95.24 | 11.2 | 21.7 | 23.1 |

| Turbine | 549.60 | 404.62 | 144.98 | 73.6 | 33.0 | 35.2 |

Disaggregating the Inverter from the Compressor and Turbine

| Compressor | 785.21 | 674.08 | 111.12 |

| Cooling heat exchanger | 46.30 | 15.51 | 30.79 |

| Heat sink heat exchanger | 107.31 | 12.07 | 95.24 |

| Inverter | 439.80 | 395.82 | 43.98 |

| Turbine | 549.60 | 418.51 | 131.09 |

Absolute difference in the values Δ compared to disaggregation

| Compressor | -15.99 | -13.82 | -2.18 |

| Cooling heat exchanger | -0.26 | -0.00 | -0.26 |

| Heat sink heat exchanger | -1.79 | -0.17 | -1.62 |

| Inverter | -7.76 | -6.98 | -0.78 |

| Turbine | -11.60 | -8.79 | -2.81 |

Relative deviation in the values δ compared to disaggregation

| Compressor | -2.00 | -2.01 | -1.92 |

| Cooling heat exchanger | -0.56 | -0.00 | -0.84 |

| Heat sink heat exchanger | -1.64 | -1.40 | -1.67 |

| Inverter | -1.73 | -1.73 | -1.74 |

| Turbine | -2.07 | -2.06 | -2.10 |

High deviation due to differences in component exergy balances

Network data (results only)| 439.80 | 15.51 | 412.23 | 12.07 | 3.5 |

Python code - This application requires knowledge of Python installation and code execution.

Support:

- Engineers Edge has tested the basic functions and operation of this application using Python 3.11.9 and supporting modules.

- THE SOFTWARE IS PROVIDED "AS IS", WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT. IN NO EVENT SHALL THE AUTHORS OR COPYRIGHT HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM, OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN THE SOFTWARE.

Source

The original data of the plant are obtained from the following publication:

T. Morosuk, G. Tsatsaronis, Advanced exergoeconomic analysis of a refrigeration machine: Part 1 — methodology and first evaluation, in: Energy Systems Analysis, Thermodynamics and Sustainability Combustion Science and Engineering Nanoengineering for Energy, Parts A and B, ASMEDC, 2011. doi: 10.1115/imece2011-62688.

Related

- Heat Loss Through a Wall Equation and Calculator Determine the steady state heat loss through a single wall.

- Heat Loss through Aluminum Framed Window Equations and Calculator Design equations and calculator example Heat Loss through Aluminum Framed Window.

- Thermal Properties of Metals

- Maximum Power Dissipation of a Transistor Equation and Calculator

- Steady Flow Vapor-Compression Refrigeration Cycle - Class 14

- ASHRAE Refrigerant Applications

- Net Refrigeration Capacity Equations and Calculator

- HVAC System and Components Design and Engineering Data

- Temperature and Pressure Data for Refrigerants

- Refrigerant Line Capacities for R22

- Refrigerant Line Capacities for 134a

- Basic Mechanical Refrigerant System

- R-717 (Ammonia) Refrigerant Line Capacities