Laser Cutting, Design For Review

Laser Cutting, Design For Review

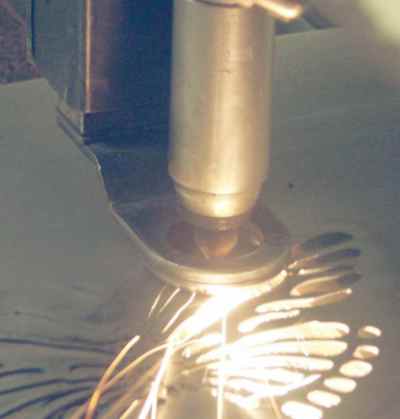

Laser cutting is a common manufacturing process employed to cut many types of materials. Materials which may be laser cut include; ferrous metals, non-ferrous metals, stone, plastics, rubber, and ceramics. Laser cutting works by directing a high power pulsed laser at a specific location on the material to be cut. The energy in the laser beam is absorbed into the surface of the material, and the energy of the laser is converted into heat, which melts or vaporizes the material. Additionally, gas is focused or blown into the cutting region to expel or blow away the molten metal and vapor from the cutting path.

|

|---|

There are several advantages of laser cutting over mechanical cutting, since the cut is performed by the laser beam, there is no physical contact with the material, therefore, contaminates cannot enter or embed into the material. Laser cutting can produce high accuracy cuts, complex shapes, cut several parts simultaneously, produce clean cutting edges which require minimal finishing, as well as, low edge loads during cutting, which will reduce distortions.

The width of laser cut or kerf, and quality of the cut edges, are effected by power of the laser, laser beam pulses, and the motion of the laser beam, and work-piece.

The following are typical cut or kerf widths resulting from laser cutting process:

| Laser Cutting kerf Width vs. Material Thickness |

||

| Material | Material Cut Thickness |

Material Removed (Kerf) |

| Aluminum | .100 | .010 |

| Plastics | .002 - .018 | 2 times the beam diameter | Steel and Iron |

0.060 0.090 0.120 0.250 |

.002 |