Related Resources: manufacturing

Morse Taper Shanks Dimensions Table

Manufacturing Engineering and Design

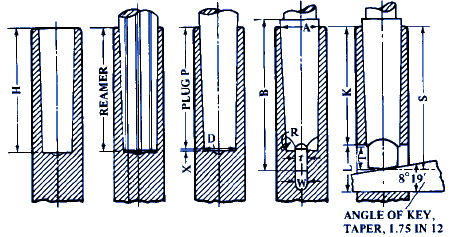

Morse standard taper shanks and sockets dimensions and tolerance chart. All units are given in inches.

The rate of taper for different numbers of Morse tapers is approximately 5/8 inch per foot in most cases. The table below is accurate to five decimal places. Morse taper shanks are used on a variety of tools, and exclusively on the shanks of twist drills.

|

Taper

Designation |

Taper

per Foot |

Taper

per Inch |

Small End

of Plug D |

Diameter End

of Socket A |

Shank

|

Depth of

Hole H |

|

|---|---|---|---|---|---|---|---|

|

Length B

|

Depth S

|

||||||

|

0

|

0.62460

|

0.05205

|

0.252

|

0.3561

|

211/32

|

27/32

|

21/32

|

|

1

|

0.59858

|

0.04988

|

0.369

|

0.475

|

29/16

|

27/16

|

25/32

|

|

2

|

0.59941

|

0.04995

|

0.572

|

0.700

|

31/8

|

215/16

|

239/64

|

|

3

|

0.60235

|

0.05019

|

0.778

|

0.938

|

37/8

|

311/16

|

31/4

|

|

4

|

0.62326

|

0.05193

|

1.020

|

1.231

|

47/8

|

45/8

|

41/8

|

|

5

|

0.63151

|

0.05262

|

1.475

|

1.748

|

61/8

|

57/8

|

51/4

|

|

6

|

0.62565

|

0.05213

|

2.116

|

2.494

|

89/16

|

81/4

|

721/64

|

|

7

|

0.62400

|

0.05200

|

2.750

|

3.270

|

115/8

|

111/4

|

105/64

|

|

Plug Depth P

|

Tang or Tongue

|

Keyway

|

Keyway to EndK

|

||||

|

Thickness t

|

Length T

|

Radius R

|

Dia.

|

Width W

|

Length L

|

||

|

2

|

0.1562

|

1/4

|

5/32

|

0.235

|

11/64

|

9/16

|

115/16

|

|

21/8

|

0.2031

|

3/8

|

3/16

|

0.343

|

0.218

|

3/4

|

21/16

|

|

29/16

|

0.2500

|

7/16

|

1/4

|

17/32

|

0.266

|

7/8

|

21/2

|

|

33/16

|

0.3125

|

9/16

|

9/32

|

23/32

|

0.328

|

13/16

|

31/16

|

|

41/16

|

0.4687

|

5/8

|

5/16

|

31/32

|

0.484

|

11/4

|

37/8

|

|

53/16

|

0.6250

|

3/4

|

3/8

|

113/32

|

0.656

|

11/2

|

415/16

|

|

71/4

|

0.7500

|

11/8

|

1/2

|

2

|

0.781

|

13/4

|

7

|

|

10

|

1.1250

|

13/8

|

3/4

|

25/8

|

1.156

|

25/8

|

91/2

|

Mechanical tolerances on taper: all sizes 0.002 in. per foot. This tolerance may be applied on shanks only in the direction that increases the rate of taper, and on sockets only in the direction that decreases the rate of taper.