Related Resources: mechanics machines

Ball Screw Design Equations and Selection Criteria

Machine Design Resources

Gear Design and Engineering

A ball screw transforms rotational motion into transitional motion. As a result, the shaft is subject to loads:

Ball Screw Design Equations and Selection Criteria:

- Applied load

- Required Torque

- Maximum Rotational Speed

- Resonance (bending) of threaded shaft

- DN force ball screw

- Ball screw life, basic dynamic rating

- Stiffness

- Accuracy

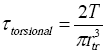

Driving Torque to Obtain Thrust

![]()

Where:

T = Driving torque (Nm)

Fa = Axial thrust force on ball screw (N)

l = Screw lead (m)

η = Efficiency

Thrust Required

Thrust is equal to the sum of all forces acting in the axial direction

Fa = FM + Ff + Fi + Fg

FM = Machining force (N)

Ff = Frictional force (N)

Fi = Inertial force (N)

Fg = Gravitational force (N)

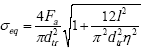

Stresses from Applied Loads

Where:

Fa = Applied axial force (N)

rtr = root radius = root diameter / 2 (m)

T = Applied Torque (N-m)

π = 3.14159

Equivalent (Von Mises) Stress

![]()

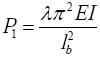

Compressive Load

P1 = Buckling load [N]

lb = Distance between mounting positions [m]

E = Elastic modulus [Pa]

I = Second moment of inertia [m4]

λ = Support factor

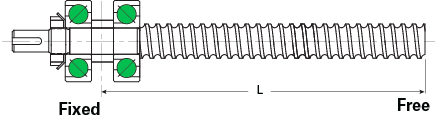

Fixed – free: λ = 0.25

Fixed – supported: λ = 2.0

Fixed – fixed: λ = 4.0, Fixed -supported = 2.0, Fixed-free = 0.25

Fixed - Free Configuration

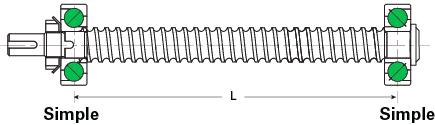

Simple - Simple Configuration

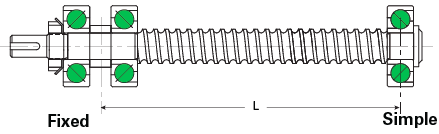

Fixed - Simple Configuration

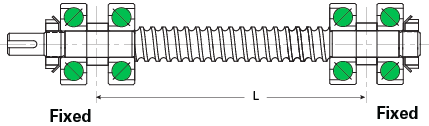

Fixed - Fixed Configuration

Basic Static Loading

- When ball screws are subjected to excessive loads in static condition (non rotating shaft), local permanent deformations are caused between the track surface and the steel balls.

- When the amount of this permanent deformation exceeds a certain degree, smooth movement will be impaired.

![]()

Where:

Coa = Basic static load rating [N, kgf, lbf]

Fs = Static safety factor

Fa = Load on shaft in axial direction [N, kgf, lbf]

| Use | Fs (Lower Limit) |

|---|---|

| Normal | 1.0 - 2.0 |

| With Impacts and Vibrations |

3.2 - 3.0 |

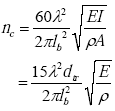

Permissible Ball Screw Speed

When the speed of a ball screw increases, the ball screw will approach its natural frequency, causing a resonance and the operation will become impossible.

Where:

nc = Critical speed [min-1]

lb = Distance between supports [m]

E: Elastic modulus [Pa]

I = Second moment of inertia [m4]

ρ = Density [kg/m3]

A = Root cross sectional area [m2]

λ = Support factor

Fixed – free: λ = 1.875

Supported – supported: λ = 3.142

Fixed – supported: λ = 3.927

Fixed – fixed: λ = 4.730

Spindle Speed and DN Drive

n = Va / l

Where:

n = Revolutions per second ( s-1 )

Va = Axial Speed (m/s)

l = Lead (m)

DN unless otherwise specified

DN ≤ 70000

D = Ball circle diameter (mm)

N = Revolutions per minute (min-1)

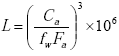

Dynamic Load Rating Ca and Life

The basic load rating Ca is the load in the shaft direction with 90% of a group of the same ball screws operating individually will reach a life of 106 (1 million) revolutions.

Where:

L = Rotation life [rev]

Ca = Basic dynamic load rating [N, kgf, lbf]

fw = Load factor

Fa = Load in shaft direction [N, kgf, lbf]

| Use | fw |

|---|---|

| Smooth operation no impacts | 1.0 - 1.2 |

| Normal operation | 1.2 - 1.5 |

| Operation with impacts and vibrations | 1.5 - 2.5 |

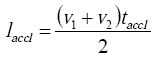

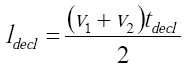

Running Lengths depending on Usage

Running distance during acceleration:

Running distance during deceleration:

References:

THK Co. Ltd

Nook Industries

University of Utah, Mechanical Engineering ME EN 7960