Machining and Grinding Plastics Review

Manufacturing Knowledge Menu

Plastics Design Resources

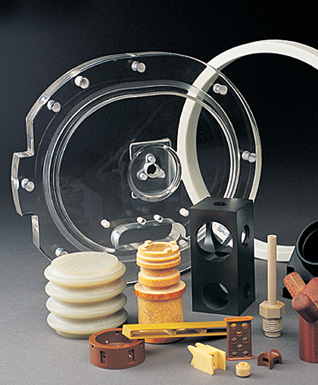

Machining and Grinding Plastics - Thermoplastics are often machined to create prototypes, production parts that cannot be molded, or to finish parts that have molded for improved dimensional and size accuracy. Thermoplastics are low strength and hardness type materials that permits high machining cutting speeds and feeds, but the low heat conductivity and greater resilience require increased relief's and less rake in order to avoid undersize cutting. Hard and sharp machine tools should be used. Plastics sometimes contain abrasives that can cause the machine tools to wear or become dull rapidly. Dull machine tools generate heat and cause the tools to cut to shallow depths or increase material flow. The depth and force applied by the machine tool should be small. When high production justifies the cost, diamond turning and boring tools are used. Diamond tools maintain sharp cutting edges and produce an excellent machined surface. They are particularly advantageous when a more abrasive plastic such as reinforced plastic is machined.

Cutting Fluids for Plastics:

Typically a small continuous stream of air or a stream of water directed at the machine tool cutting area, improves the turning and cutting of plastics as it prevents the heating of the tool and causes the chips to remain brittle and to break rather than become sticky and gummy. A zero or slightly negative back rake and a relief angle of 8 to 12 should be used on machine cutting tools. For thermoplastics machine tool cutting speeds generally range from 250 to 400 ft/min (75 to 120 m/min) and for thermosetting plastics from 400 to 1,000 ft/min (120 to 300 m/min).

Milling Plastics:

Tool feed speeds of 400 to 1,000 ft/min (120 to 300 m/min) should be used, with angles similar to those on a single-point (lathe or turning) tool with a 0 to 10 negative rake angle. Good results have been obtained by hobbing plastic gears with carbide-tipped hobs. Recommended tool materials are M2 and M7 high-speed steels and C2 carbide. In drilling, speeds range from 150 to 400 ft/min (45 to 120 m/min), and the recommended drill geometry is given in Table 13.4.6. Tool materials are M1, M7, and M10 high-speed steel. Usually the drill cuts undersize; drills 0.002 to 0.003 in (0.05 to 0.075 mm) oversize should be used.

Sawing Plastics:

Either precision or buttress tooth forms may be used, with a pitch ranging from 3 to 14 teeth/in (1.2 to 5.5 teeth/cm), the thicker the material the lower the number of teeth per unit length of saw. Cutting speeds for thermoplastics range from 1,000 to 4,000 ft/min (300 to 1,200 m/min) and for thermosetting plastics from about 3,000 to 5,500 ft/min (900 to 1,700 m/min), with the higher speeds for thinner stock. High-carbon-steel blades are recommended. An air blast is helpful in preventing the chips from sticking to the saw. Abrasive saws operating at 3,500 to 6,000 ft/min (1,000 to 1,800 m/min) are also used for cutting off bars and forms.

Threading Plastics:

Plastics are tapped and threaded with standard machine or hand tools. Ground M1, M7, or M10 high-speed steel taps with large polished flutes are recommended. Tapping speeds are usually from 25 to 50 ft/min (8 to 15 m/min); water serves as a good cutting fluid as it keeps the material brittle and prevents sticking in the flutes. Thread cutting is generally accomplished with tools similar to those used on brass. Reaming is best accomplished in production by using tools of the expansion or adjustable type with relatively low speeds but high feeds. Less material should be removed in reaming plastics than in reaming other materials.

Polishing & Buffing Plastics:

Polishing is done with special compounds containing wax or a fine abrasive. Buffing wheels for plastics should have loose stitching. Vinyl plastics can be buffed and polished with fabric wheels of standard types, using light pressures. Thermoplastics and thermosets can be ground with relative ease, usually by using silicon carbide wheels. As in machining, temperature rise should be minimized.

|

|