Plastic Extrusion Design Manufacturing Review

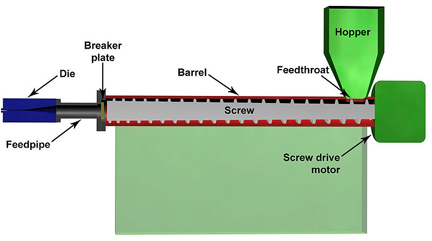

Plastic Extrusion Manufacturing is the process where a polymer or plastic material is fed into a heated cavity or cylinder and a hydraulic or pneumatic actuator or screw mechanism compresses and forces the molten plastic material through a tool die orifice. The plastic extruded material then cools and is further processed into the final part. Plastic extrusion parts and manufacturing is a high production process.

There are many shape - geometries that are possible when using extrusion. Thin film (flat or tubular) is the most common product. Other extruded products include pipe and tubing, coated paper or foil, monofilaments and textile fibers, flat sheet (anything over 0.010 inch (0.25 mm)), wire and cable covering, and a great variety of profiles such as window frames, gaskets and channels, and house siding. The products can be cut to length or rolled up as needed.

Tooling costs for plastic extrusions are modest and generally considered inexpensive compared to metal extrusion.

Plastic extrusion materials maybe the following: ABS, acrylic, butyrate, fiberglass, nylon, polycarbonate, polyethylene (PE), polyethylene terepthalate glycol (PETG), polypropylene (PP), polyamide, polystyrene, PTFE, polyurethane or urethane, and PVC.

Standard industrial shapes created by plastic extrusion are films, sheet, rod or wire, cross sectional profiles, tubing, hose, pipes, and more. Plastic extrusion length are only limited to the manufacturing process machines capability. Very large area cross sections are possible by plastic extrusion manufacturing.

The design of custom extruded cross section shapes should have uniform wall section, and include generous radii at all surface intersections. Varying and high density cross sections should be avoided.

|

|---|