Related Resources: pumps

Hydraulic Ram for Pumping Water

Engineering Applications and Design

Hydraulics Engineering and Design

Fluids Engineering and Design

Pump Types, Applications and Resources

Operation and Design Hydraulic Ram Pump for Pumping Water

Also referred to as Hydram

Premium Membership Required to view Document/Book

Open: Hydraulic Ram for Pumping Water

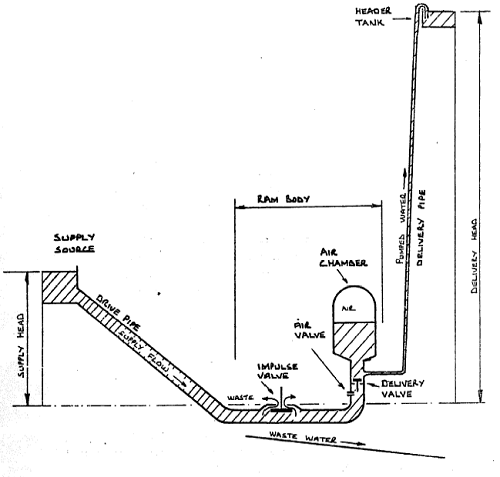

The automatic hydraulic ram is a pumping device that has been widely used for nearly a century in rural areas, for lifting water to heights of over 100 meters. It is an ideal machine for water pumping if certain condition is satisfied, because it works solely on the power from falling water carried in a pipe from a spring, stream or river, without any need for an additional power source. It is completely automatic, and has an exceptional record of trouble free operation. It cannot be used everywhere, however. It cannot be used to pump still water from a well, pond or lake, unless there is a Separate, flowing water source nearby.

The simple ram pump described in this manual has been made and used since 1948, but we have only limited information on its performance. This has been taken from the VITA publication (Ref. 6.6 in the bibliography) and our own very limited laboratory tests (Section 5). We would welcome information from anyone who has built one of these r8m pumps, operated it over a long period, and who has ale0 measured the pumping rate and surveyed the site conditions.

Although this method of making a ram pump ha8 already been published by VITA (6.6.), we have written the manual to do two things. We hope to demonstrate to field workers how they can build the ram and have the confidence to overcome any difficulties in installation and tuning. We also hope to provide information to those with 8ome technical and workshop experience that will enable them to manufacture larger rams.

TOC

In Part 1, we describe how a simple ram pump can be made from commercial pipe fittings, how to choose a site for the ram, how to install and adjust the ram, and the sort of maintenance that the ram pump will need during its working life. We have tried to write the manual in non-technical language so that it can be used by people with little or no technical training.

In part 11, we describe in greater detail the range and we describe in greater detail the range and limit8 of operation of ram pump, and the different material8 that have been used to make them. We have taken information given in the trade literature of a commercial ram manufacturer, Blake's Hydrams Ltd., (Ref. 6.9), to describe the simple calculations that you will need to design a different sized ram pump for different site conditions. We also include in Part 11 the results of our limited laboratory tests on the ram, which describe8 the tuning procedure.

We have not attempted to describe the complex relationship involved in the hydraulic behavior of the water moving through the ram, this is very difficult to follow unless you have substantial experience of fluid mechanics. An annotated bibliography listing the main sources of information that we used to write this manual is included in the last section of Part 11.

TOC

PART 1

How to make and install a simple Ram Pump constructed from water pipe fittings.

A Description

How it works

Is your site suitable for the ram?

Measuring the flow of water at the source.

Measuring a small flow, such as a spring.

Measuring larger flows.

Measuring the supply and delivery heads.

Designing the ram.

How much water can the ram pimp.

Choosing the size of the drive pipe.

Choosing the size of the delivery pipe.

Choosing the size of header tank.

Building the ram.

Making the impulse valve.

An alternative impulse valve

Making the delivery valve.

Making the air chamber.

Making the mounting legs.

Assembling the ram at the site.

Tuning the ram.

What to do if the ram doesn't work.

Maintenance of the ram after installation.

The supply source

Maintenance tasks

Frequency of maintenance.

Part II

A more technical Look at Hydraulic Ram Pumps

Introduction

Ram performance

Some design considerations.

Construction materials.

Drive pipe

Impulse valve

Delivery Valve.

Air chamber

Air valve i

Delivery pipe from ram to header tank.

Designing the ram side.

Laboratory tests carried out on the ram built from Part1 instructions.

Operating the ram

0bservations on ram behavior

Testing the ram

Test results

Annotated bibliography

Appendix

Some suggestions for improvements to the ram