Related Resources: calculators

V-Belt Classical Speed to Horsepower Formulas and Calculator for Cross Sections

Belt Drive Design and Engineering

Mechanical Gear Design and Engineering

V-Belt Classical Speed to Horsepower Ratings Formulas and Calculator for Cross Sections

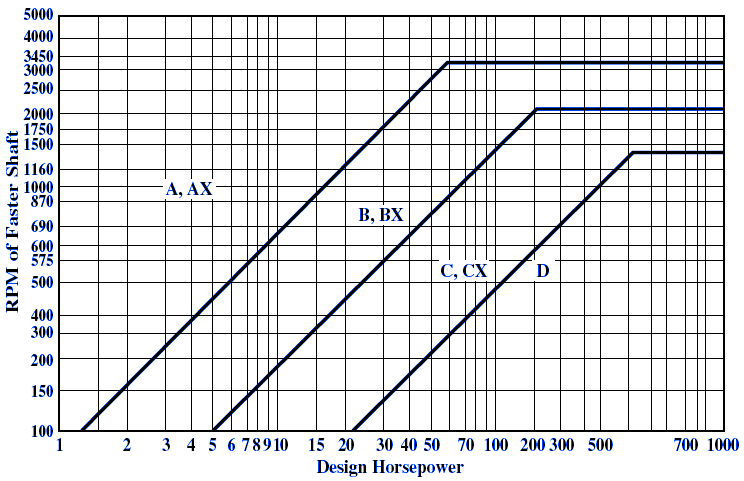

Cross Section Design Selection: Use the chart given below to determine if the V-belt cross section for any combination of design horsepower and speed of the faster shaft. When the intersection of the design horsepower and speed of the faster shaft falls near a line between two areas on the chart, the possibilities in both areas should be investigated. Special circumstances (such as space limitations) may lead to a choice of belt cross section different from that indicated in the chart.

Design HP = Basic Horsepower Rating x Service Factor

Basic Horsepower Rating Formulas

V-Belt Cross Section "A"

HP = dp rk [ 1.004 - 1.652 / dp - 1.5747 x 10-4 ( dp r )2 - 0.2126 log( dp r ) ] + 1.652 r ( 1 - 1 / KSR )

V-Belt Cross Section "AX"

HP = dp rk [ 1.462 - 2.239 / dp - 2.198 x 10-4 ( dp r )2 - 0.4238 log( dp r ) ] + 2.239 r ( 1 - 1 / KSR )

V-Belt Cross Section "B"

HP = dp rk [ 1.769 - 4.372 / dp - 3.081 x 10-4 ( dp r )2 - 0.3658 log( dp r ) ] + 4.372 r ( 1 - 1 / KSR )

V-Belt Cross Section "BX"

HP = dp rk [ 2.051 - 3.532 / dp - 3.097 x 10-4 ( dp r )2 - 0.5735 log( dp r ) ] + 3.532 r ( 1 - 1 / KSR )

V-Belt Cross Section "C"

HP = dp rk [ 3.325 - 12.07 / dp - 5.828 x 10-4 ( dp r )2 - 0.6886 log( dp r ) ] + 12.07 r ( 1 - 1 / KSR )

V-Belt Cross Section "CX"

HP = dp rk [ 3.272 - 6.655 / dp - 5.298 x 10-4 ( dp r )2 - 0.8637 log( dp r ) ] + 6.655 r ( 1 - 1 / KSR )

V-Belt Cross Section "D"

HP = dp rk [ 7.160 - 43.21 / dp - 1.384 x 10-4 ( dp r )2 - 1.454 log( dp r ) ] + 43.21 r ( 1 - 1 / KSR )

Where:

dp = pitch diameter of small sheave, in.

r = rpm of the faster shaft.

rk = r / 1000

KSR = speed ratio factor given in the accompanying Table below.

Speed Ratio Range = Dp / dp

Where:

Dp = Pitch of Large Sheave

dp = Pitch of Small Sheave

|

Speed Ratio Range

|

KSR

|

|

1.00 - 1.01

|

1.0000

|

|

1.02 - 1.04

|

1.0112

|

|

1.05 - 1.07

|

1.0226

|

|

1.08 - 1.10

|

1.0344

|

|

1.11 - 1.14

|

1.0463

|

|

1.15 - 1.20

|

1.0586

|

|

1.21 - 1.27

|

1.0711

|

|

1.28 - 1.39

|

1.0840

|

|

1.40 - 1.64

|

1.0972

|

|

> 1.64

|

1.1106

|

FPM to RPM Equation:

r = s / ( π d )

RPM to FPM Equation:

s = r π d

Where:

r = rpm

s = ft / min

d = diameter of pulley in ft

Related:

- Synchronous Timing Belt Tooth Section Dimensions Table per ANSI / RMA IP-24

- Synchronous Timing Belt Pulley Dimensions Table per ANSI / RMA IP-24

- Synchronous Timing Belt Lengths and Tolerances per. ANSI RMA IP-24 Table

- Service Factors Synchronous Timing Belts

- Synchronous Timing Belt Standard Widths and Tolerances Table

- Synchronous Belt Standard Pulley Diameters ANSI/RMA IP-24 Table

- Timing Belt Pulley Mechanical Tolerances per. ANSI RMA IP-24

References:

ANSI / RMA IP-24