Related Resources: materials

Heat Treating Steel Time vs Temperature and Case Harden Thickness

Engineering Materials

Applications & Design

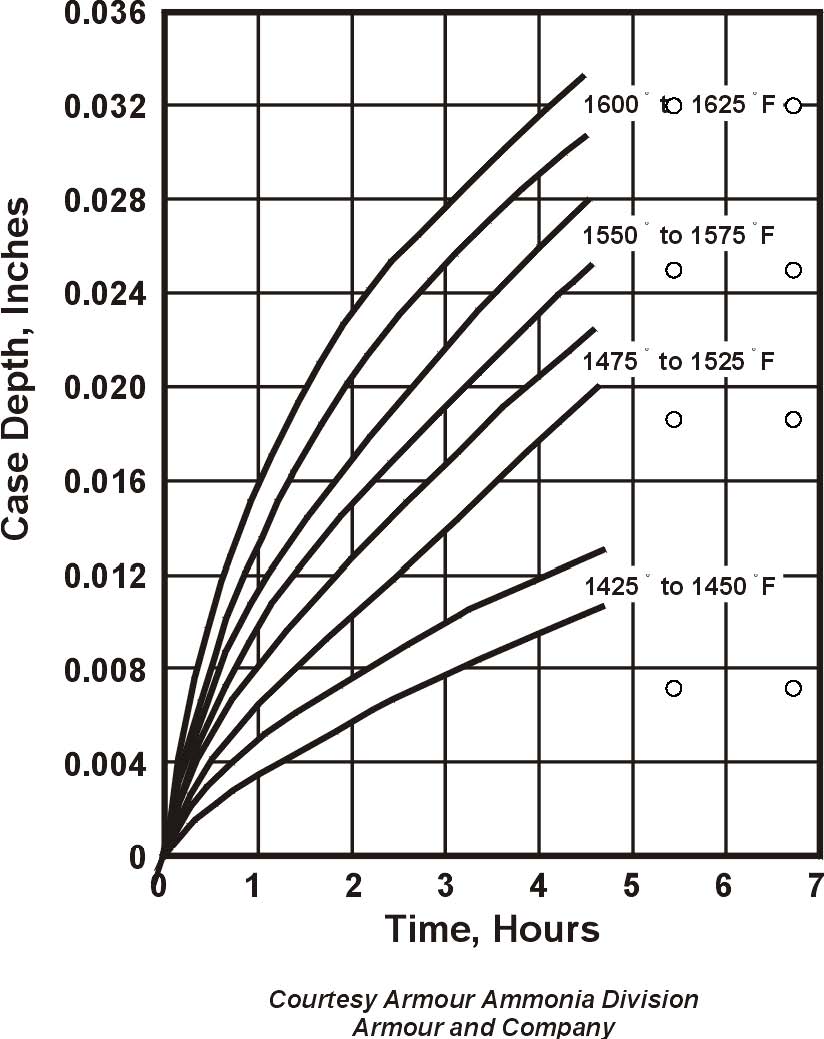

The following table chart specifies the Heat Treating Time at known Temperature and the resulting Case Harden Depth.

|

Heat Treat Time Hours |

Temperature, ºF |

||||||||||

|

1400 |

1450 |

1500 |

1550 |

1600 |

1650 |

1700 |

1750 |

1800 |

1850 |

Case Depth Thickness Inches |

|

|

1 |

0.008 |

0.010 |

0.012 |

0.015 |

0.018 |

0.021 |

0.025 |

0.029 |

0.034 |

0.040 |

|

|

2 |

0.011 |

0.014 |

0.017 |

0.021 |

0.025 |

0.030 |

0.035 |

0.041 |

0.048 |

0.056 |

|

|

3 |

0.014 |

0.017 |

0.021 |

0.025 |

0.031 |

0.037 |

0.043 |

0.051 |

0.059 |

0.069 |

|

|

4 |

0.016 |

0.020 |

0.024 |

0.029 |

0.035 |

0.042 |

0.050 |

0.059 |

0.069 |

0.079 |

|

|

5 |

0.018 |

0.022 |

0.027 |

0.033 |

0.040 |

0.047 |

0.056 |

0.066 |

0.077 |

0.089 |

|

|

6 |

0.019 |

0.024 |

0.030 |

0.036 |

0.043 |

0.052 |

0.061 |

0.072 |

0.084 |

0.097 |

|

|

7 |

0.021 |

0.026 |

0.032 |

0.039 |

0.047 |

0.056 |

0.066 |

0.078 |

0.091 |

0.105 |

|

|

8 |

0.022 |

0.028 |

0.034 |

0.041 |

0.050 |

0.060 |

0.071 |

0.083 |

0.097 |

0.112 |

|

|

9 |

0.024 |

0.029 |

0.036 |

0.044 |

0.053 |

0.063 |

0.075 |

0.088 |

0.103 |

0.119 |

|

|

10 |

0.025 |

0.031 |

0.038 |

0.046 |

0.056 |

0.067 |

0.079 |

0.093 |

0.108 |

0.126 |

|

|

11 |

0.026 |

0.033 |

0.040 |

0.048 |

0.059 |

0.070 |

0.083 |

0.097 |

0.113 |

0.132 |

|

|

12 |

0.027 |

0.034 |

0.042 |

0.051 |

0.061 |

0.073 |

0.087 |

0.102 |

0.119 |

0.138 |

|

|

13 |

0.028 |

0.035 |

0.043 |

0.053 |

0.064 |

0.076 |

0.090 |

0.106 |

0.123 |

0.143 |

|

|

14 |

0.029 |

0.037 |

0.045 |

0.055 |

0.066 |

0.079 |

0.094 |

0.110 |

0.128 |

0.149 |

|

|

15 |

0.031 |

0.039 |

0.047 |

0.057 |

0.068 |

0.082 |

0.097 |

0.114 |

0.133 |

0.154 |

|

|

16 |

0.032 |

0.039 |

0.048 |

0.059 |

0.071 |

0.084 |

0.100 |

0.117 |

0.137 |

0.159 |

|

|

17 |

0.033 |

0.040 |

0.050 |

0.060 |

0.073 |

0.087 |

0.103 |

0.121 |

0.141 |

0.164 |

|

|

18 |

0.033 |

0.042 |

0.051 |

0.062 |

0.075 |

0.090 |

0.106 |

0.125 |

0.145 |

0.169 |

|

|

19 |

0.034 |

0.043 |

0.053 |

0.064 |

0.077 |

0.092 |

0.109 |

0.128 |

0.149 |

0.173 |

|

|

20 |

0.035 |

0.044 |

0.054 |

0.066 |

0.079 |

0.094 |

0.112 |

0.131 |

0.153 |

0.178 |

|

|

21 |

0.036 |

0.045 |

0.055 |

0.067 |

0.081 |

0.097 |

0.114 |

0.134 |

0.157 |

0.182 |

|

|

22 |

0.037 |

0.046 |

0.056 |

0.069 |

0.083 |

0.099 |

0.117 |

0.138 |

0.161 |

0.186 |

|

|

23 |

0.038 |

0.047 |

0.058 |

0.070 |

0.085 |

0.101 |

0.120 |

0.141 |

0.164 |

0.190 |

|

|

24 |

0.039 |

0.048 |

0.059 |

0.072 |

0.086 |

0.103 |

0.122 |

0.144 |

0.168 |

0.195 |

|

|

25 |

0.039 |

0.049 |

0.060 |

0.073 |

0.088 |

0.106 |

0.125 |

0.147 |

0.171 |

0.199 |

|

|

26 |

0.040 |

0.050 |

0.061 |

0.075 |

0.090 |

0.108 |

0.127 |

0.150 |

0.175 |

0.203 |

|

|

27 |

0.041 |

0.051 |

0.063 |

0.076 |

0.092 |

0.110 |

0.130 |

0.153 |

0.178 |

0.206 |

|

|

28 |

0.042 |

0.052 |

0.064 |

0.078 |

0.094 |

0.112 |

0.132 |

0.155 |

0.181 |

0.210 |

|

|

29 |

0.042 |

0.053 |

0.065 |

0.079 |

0.095 |

0.114 |

0.134 |

0.158 |

0.185 |

0.214 |

|

|

30 |

0.043 |

0.054 |

0.066 |

0.080 |

0.097 |

0.116 |

0.137 |

0.161 |

0.188 |

0.217 |

|

For Example: 4320 carburized at 1700ºF for 11 hours at temperature would attain “case depth” of 0.083 inches. If 0.100 inches were specified it would require 16 hours. Source: Metal Progress, August 1943.

Case Depth vs Time Heat Treating Table Graph

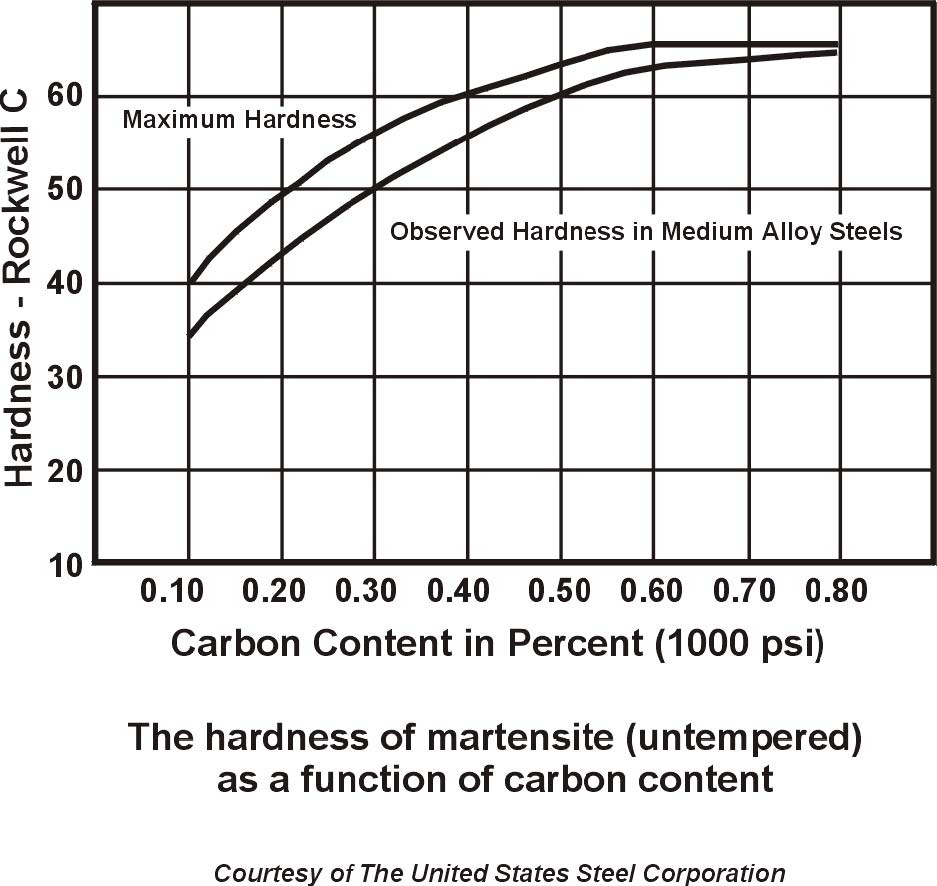

Hardness Vs. Carbon Content of Steel

Related

- Alloy Steel Heat Treating

- Carbon Steel Typical Heat Treatment

- Chromium Nickel Steels Not Hardenable by Heat Treating

- Heat Treatment Hardness vs Temperature

- Heat Treating Aluminum Alloys

- Heat Treatment - Annealing

- Heat Treatment Review

- Heat Treating Stainless Steels

- Heat Treating Terms Definitions # 1

- Heat Treating Terms Definitions #2

- Heat Treating Tool Steels

- Induction Hardening Review

- Normalizing Annealing Tool Steels