Surface Roughness (Finish) Review and Equations - Engineers Edge

Manufacturing Knowledge Menu

Surface Roughness Conversion Chart

Surface roughness ot texture is the measure if the finer surface irregularities in the surface texture and is composed of three components: roughness, waviness and form. These are the result of the manufacturing process employed to create the surface.

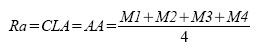

Surface roughness average (Ra), also know as arithmetric average (AA) is rated as the arithmetic average deviation of the surface valleys and peaks expressed in micro inches or micro meters. ISO standards use the term CLA (Center Line Average). Both are interpreted identical.

Where Ra is the arithmetic average value or departure from profile front eh center line, the equation for four as-measured values:

Where:

Mx = measure value

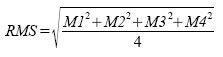

Root Mean Square (RMS / Rq / Rs) can be calculated by:

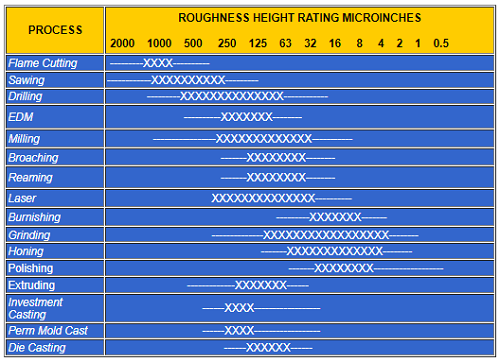

The ability of a manufacturing operation to produce a specific surface roughness depends on many factors. For example, in end mill cutting, the final surface depends on the rotational speed of the end mill cutter, the velocity of the traverse, the rate of feed, the amount and type of lubrication at the point of cutting, and the mechanical properties of the piece being machined. A small change in any of the above factors can have a significant effect on the surface produced.

SURFACE ROUGHNESS AVERAGE OBTAINABLE BY

COMMON PRODUCTION METHODS

References:

ASME B46.1

- ASME Y14.36M - 1996 Surface Texture Symbols

- ISO 468:1982 “Surface roughness — parameters. Their values and general rules for specifying requirements.”

- ISO 4287:1997 “Surface texture: Profile method — Terms, definitions and surface texture parameters.”

- ISO 4288:1996 “Surface texture: Profile method — Rules and procedures for the assessment of surface texture.” Includes specifications for precision reference specimens, and roughness comparison specimens, and establishes requirements for stylus-type instruments.

- ISO 8785:1998 “Surface imperfections — Terms, definitions and parameters.

- ISO 10135-1:CD “Representation of parts produced by shaping processes — Part 1: Molded parts.”