Related Resources: gears

Parallel-Sided Splines Table Calculator

Gear Design Engineering Tools Data Knowledge Menu

SAE Parallel Side Splines Table of Sizes and Dimensions

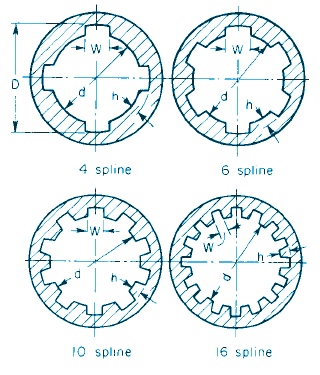

Parallel-side spline's have been standardized by the SAE for 4, 6, 10, and 16 spline fittings.

* Tolerance allowed of -0.001 in for shafts 3⁄4 to 13⁄4 in, inclusive; of -0.002 for shafts 2 to 3 in, inclusive; -0.003 in for shafts 31⁄2 to 6 in, inclusive, for 4-, 6-, and 10-spline fittings; tolerance of -0.003 in allowed for all sizes of 16-spline fittings.

^ Tolerance allowed of -0.002 in for shafts 3⁄4 in to 13⁄4 in, inclusive -0.003 in for shafts 2 to 6 in, inclusive, for 4-, 6-, and 10-spline fittings; tolerance of -0.003 allowed for all sizes of 16-spline fittings.

Figure 1, Parallel-sided splines.

Source:

Marks Standard Handbook for Mechanical Engineers

Related:

- Spline Transmitted Torque and Pressure Analysis Formula and Calculator

- Involute Spline Engineering Drawing Data

- Involute Spline ANSI B92.1 Equations and Design

- Involute Spline and Serration Universal Design Calculator

- Spline Socket Go and No Go Gages

- The Shaft Design Book

- Key and Spline Drive Bit Tools per. ASME B18.3

- Torque Applied Deformation and Stress of a Shaft with Four Keyways Equations and Calculator

- Torque Applied Deformation and Stress of a Shaft with One Spline Equations and Calculator

- Torque Applied Deformation and Stress of a Shaft with Two Splines Equations and Calculator

- Torque Applied Deformation and Stress of a Shaft with Four Splines Equations and Calculator