Related Resources: hardware

Bolt Fastener Tightening Methods Review

Torque Design Menu

Bolt Preload Equations

Bolt Torque Fastener Tightening Methods Review

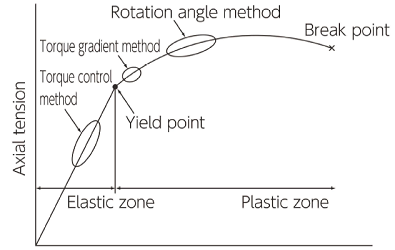

Torque Control Method: Bolt tightening is controlled by a specific torque value. This is the most common method utilized. This is a reasonable way of tightening control and operation. Tighten torque is not influenced by the bolt length and is easy to standardize. The bolt efficiency will be low due to the wide tolerance of accuracy of the tension applied by the bolt which is typically in the range of ± 6% when using verified torque tools.

Rotation Angle Method: The fastener tightening is facilitated by the degrees of angle rotation which is determined from the start of contact (seating) of the bolt head to final rotation. The tightening is defined as a specific number of turns or an angle of rotation. This method is typically used to tighten the fastener within the plastic zone which allows for a lower dispersion of axial tension during end item loading. Since the tightening is beyond the yield point, there is a limitation for additive loading to the joint. Developing a specification for the tightening angle can be a complex process.

Torque Gradient Method: The tightening is conducted by the variation of the torque gradient against the rotating angle at the the point. The variation is monitored and carried out with a mathematical process or by a electronic measuring device. Since the dispersion of the axial load is low, it is possible to design for a large bolt efficiency. inspection of the bolt itself is possible even after tightening.

Elongation Measurement Method: Tightening is controlled by the elongation of the bolt generated by the bolt tightening. The elongation is measured by a micrometer, ultrasonic, or an embedded gauge sensor in the bolt or stud. The load dispersion within the bolt is high and the efficiency of the bolted joint is large. Additive loading and bolt re-tightening is possible.

Loading Method: The nut is tightened while applying tension loading to the bolt as a pre-load. The total axial tensile loading of the bolt is generated after releasing the axial load applied during tightening. Axial tension can be directly controlled. Torsion stress is minimized or not generated. tightening fixture or method is required.

Thermal Heating Method: Tightening is controlled by the variation of bolt elongation before and after heating the bolt. Space and force are not required for tightening. There can be challenges to defining the relation between heat energy and axial tension. temperature control can be difficult.

Relationship between torque and strain.

Manual preloading methods for bolt torque applied accuracy and relative costs.

| Preload Method |

Accuracy

|

Relative Cost

|

| Feel |

± 35 %

|

1

|

| Torque wrench |

± 25 %

|

1.5

|

| Turn of nut |

± 15 %

|

3

|

| Preload indicating washer |

± 10 %

|

7

|

|

Sensor wrench |

± 15 %

|

8

|

| Sensor wrench yield point sensing |

± 8 %

|

8

|

| Bolt elongation |

± 3 - 5 %

|

15

|

| Strain gages |

± 1 %

|

20

|

Related:

- Torque Wrench Adapter for Reduced Arm Equation and Calculation

- Torque Clamp Force Calculator

- Stud Preload Calculator

- Bolt Preload Tension Equation and Calculator

- Bolt Preload Tension Force Calculator

- Torque vs Tension Bolts Table Chart SAE J429 Bolts

- Bolt Multiple Diameters Change of Length Under Axial Force Formula and Calculator